Plastic Machined Parts

Home » Work Gallery | Custom Machined Parts » Plastic Machined Parts

High precision plastic machined parts from China, CNC machining services

Precision CNC Machining for High-Quality Plastic Parts by SYM.

With over 25 years of experience, SYM Precision Machining has been a trusted partner for high-precision plastic machined parts, delivering exceptional quality and precision to customers worldwide. We specialize in machining a wide variety of plastic materials, tailored to meet the specific needs of each application.

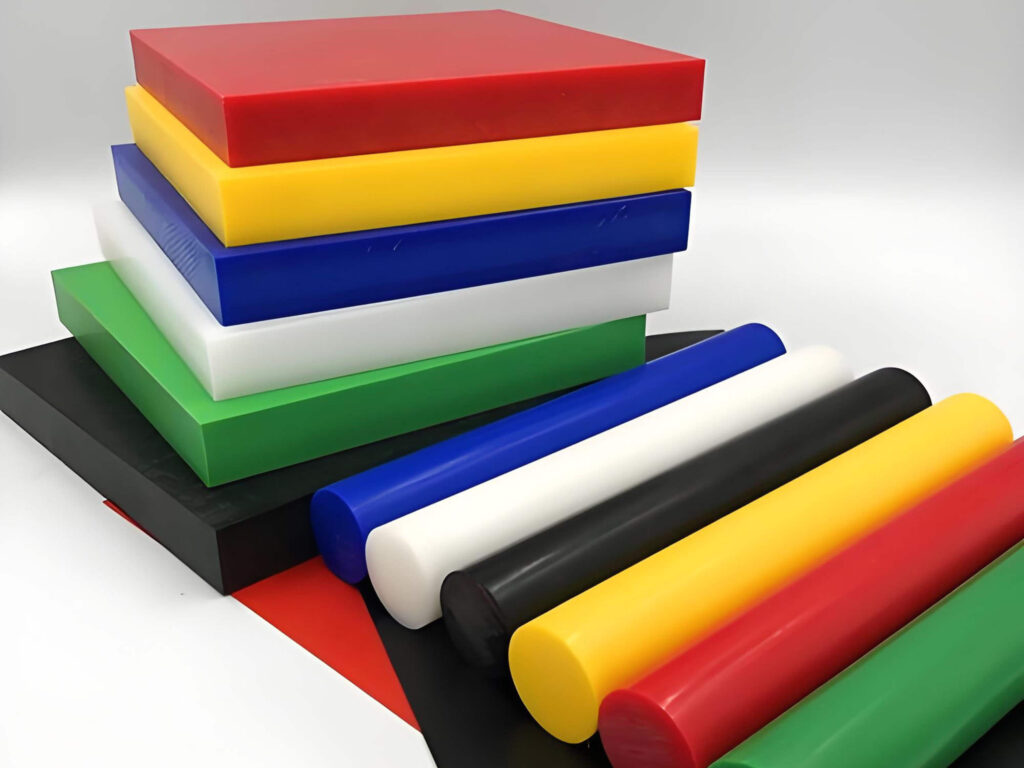

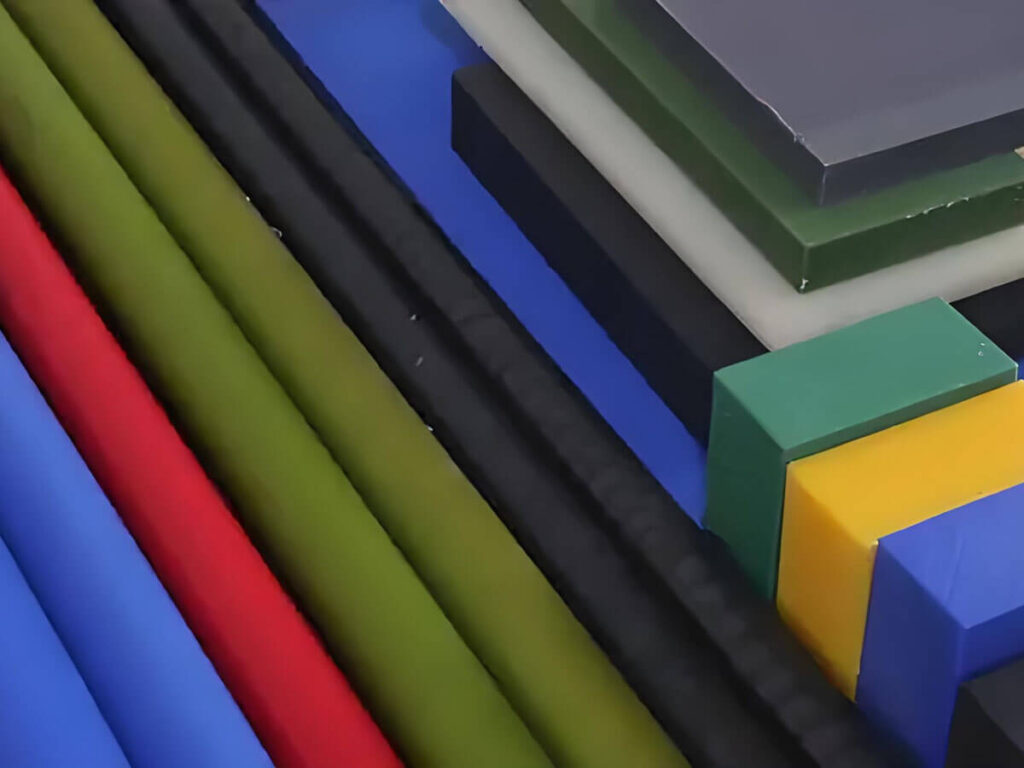

Types of Plastic Machined Parts

We work with a comprehensive range of plastic materials, including:

POM (Delrin, Acetal)

High strength, low friction, and excellent dimensional stability.

Teflon (PTFE)

Outstanding chemical resistance and low friction properties.

PE (UPE)

High wear resistance, often used for sliding and bearing applications.

ABS

Strong, lightweight, and versatile for various applications.

PVC

Excellent chemical resistance, ideal for piping and fittings.

Nylon (PA)

High toughness and wear resistance, widely used for gears and bearings.

PEEK

Exceptional heat resistance and strength, suitable for high-performance industries.

PVDF

Outstanding resistance to harsh chemicals and UV exposure.

PC (Polycarbonate)

High impact resistance and transparency, often used in optical and structural applications.

Deformation Issues in CNC Plastic Machining

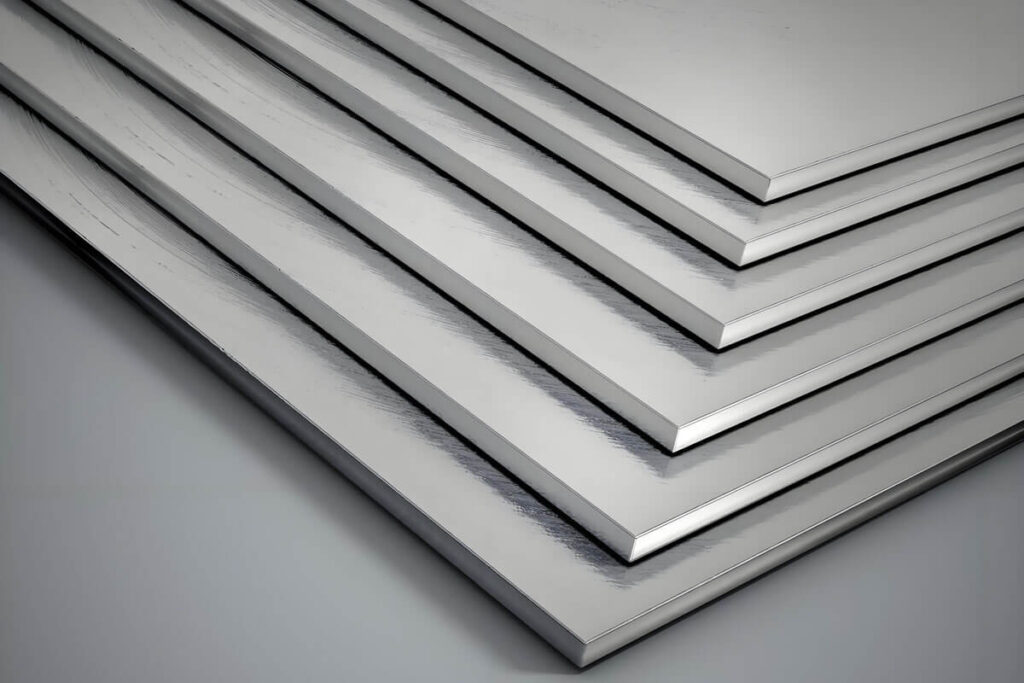

Plastics have lower stiffness, higher thermal expansion, and softer mechanical properties compared to metals, making them more prone to deformation during CNC machining. Common causes of deformation include:

Thermal Expansion

Heat generated during cutting can expand the material, altering dimensions.

Cutting Forces

Excessive forces can flex or distort the workpiece.

Material Stress

Internal stresses in the plastic can release and cause warping during machining.

How SYM Minimizes Plastic Deformation

Plastic materials are widely used in various industries, but they present unique challenges during CNC machining, particularly regarding deformation. At SYM Precision Machining, we apply our expertise to minimize deformation and meet strict tolerance requirements, ensuring high-quality results for every project.

Controlled Cutting Parameters

Lower cutting speeds and feeds to reduce heat generation. Use sharp tools to minimize cutting forces.

Cooling and Lubrication

Apply appropriate coolants or air streams to keep the material cool during machining.

Workpiece Support

Provide adequate clamping and support to prevent movement or bending.

Progressive Machining

Remove material gradually in multiple passes to reduce stress concentration.

Post-Machining Stabilization

Allow parts to stabilize after machining to detect and correct any residual deformation.

Tolerance for CNC Machined Plastic Parts

At SYM, we follow ISO 2768-m (medium tolerance) standards for general machining tolerances unless specified otherwise in customer drawings. Typical tolerances include:

Dimensional Tolerance

±0.254 mm (±0.01 inches) as standard.

Custom Tolerances

Tighter tolerances are achievable upon request, considering the material’s machinability and application requirements.

| Basic size ranges (mm) | Tolerance Class Description for Linear Dimensions | |||

| f (fine) | m (medium) | c (coarse) | v (very coarse) | |

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | — |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4 |

| Radi and Chamfer | Tolerance Class Description for Radii and Chamfer Heights | |||

| 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

| Angle Short Side Length | Tolerance Class Description for Angular Dimensions | |||

| up to 10 | ±1° | ±1° | ±1°30′ | ±3° |

| over 10 up to 50 | ±0°30′ | ±0°30′ | ±1° | ±2° |

| over 50 up to 120 | ±0°20′ | ±0°20′ | ±0°30′ | ±1° |

| over 120 up to 400 | ±0°10′ | ±0°10′ | ±0°20′ | ±0°30′ |

| over 400 | ±0°5′ | ±0°5′ | ±0°10′ | ±0°20′ |

Advantages of CNC Machining Plastic Parts Over Injection Molding

No Tooling Cost

CNC machining does not require expensive mold, making it ideal for low-volume production or prototypes.

Faster Turnaround

CNC machining allows rapid production without waiting for mold fabrication.

Greater Material Versatility

CNC machining accommodates specialty plastics and composites that might not be suitable for injection molding.

Superior Precision

CNC machining achieves tighter tolerances and finer details compared to injection molding.

Design Flexibility

CNC machining allows for frequent design changes without additional tooling cost.

Key Considerations for Plastic Machining

Material-Specific Behavior

Understand the plastic's thermal and mechanical properties to select the right machining strategy.

Tool Selection

Use tools designed for plastics to reduce burrs and improve surface quality.

Final Application

Factor in the part's operating environment (temperature, load) when defining tolerances and finishes.

SYM’s Expertise in Precision Plastic Machining

ISO Standards Compliance

We adhere to industry standards, ensuring consistent quality and precision.

Experience and Technology

Our 25+ years of experience and advanced CNC machines allow us to overcome machining challenges, including deformation issues.

Custom Solutions

Tailored strategies for each project, from material selection to final inspection, deliver optimal results.

Plastic Machined Parts Gallery

Get Your Parts Into Production Today!

Contact us today for a custom solution to your plastic machining needs