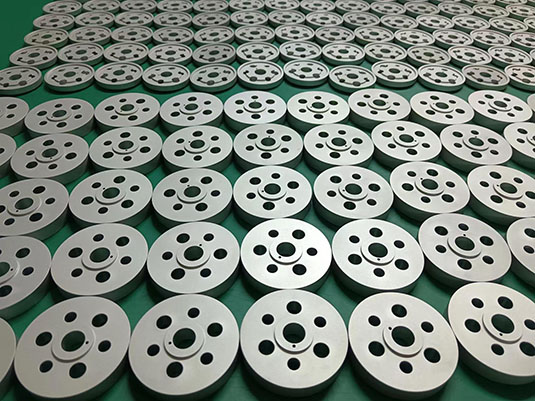

Aluminum machined parts

Home » Work Gallery | Custom Machined Parts » Aluminum Machined Parts

China's top aluminum machined parts manufacturer offers quality solutions

You’ll get a wide range of high-quality precision aluminum machined parts from SYM precision machining,

At SYM Precision Machining, we specialize in providing a wide range of precision CNC aluminum machined parts that are delivered on time and meet the highest quality standards. With over 25 years of experience in the machining industry, we have earned a reputation for manufacturing high-performance aluminum components for a variety of industries, including automation, robotics, and aerospace.

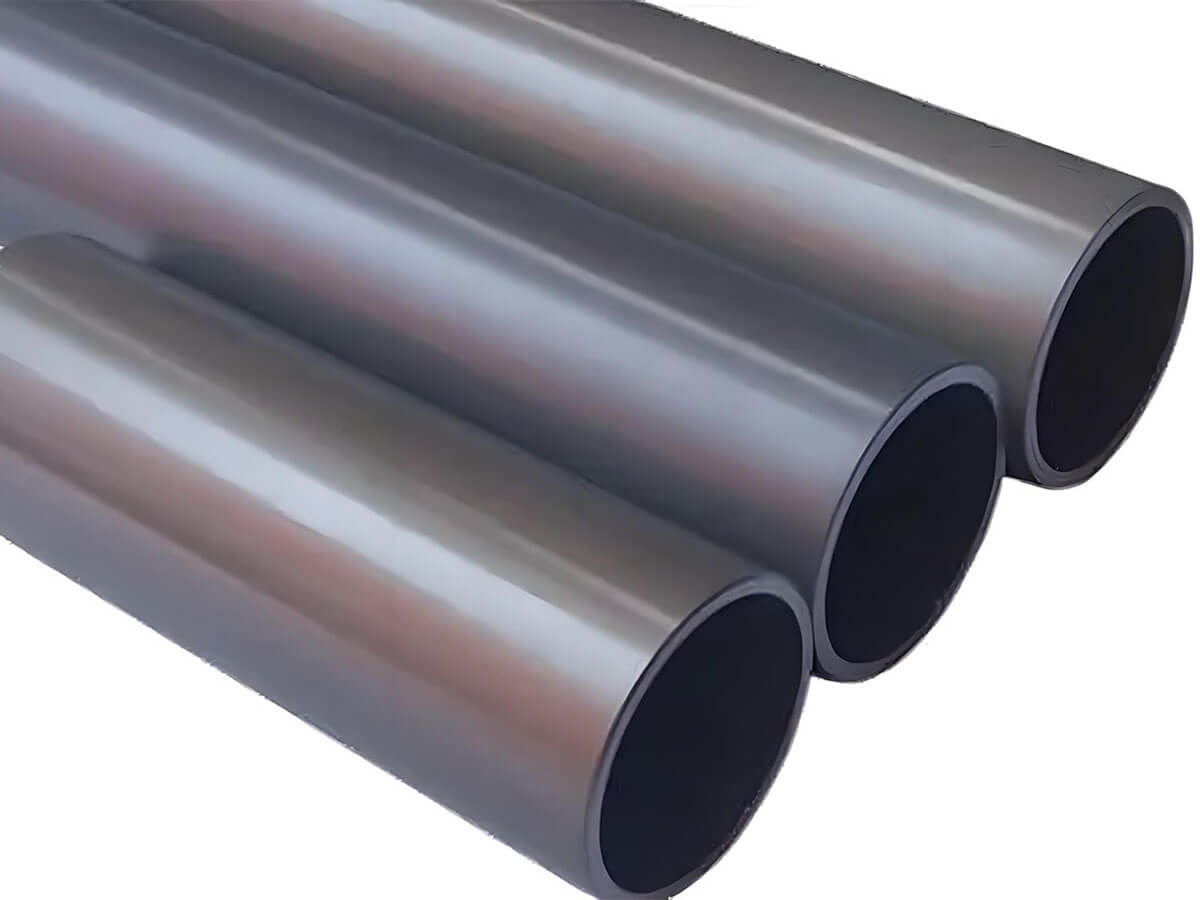

Aluminum is a versatile material known for its lightweight, strength, and corrosion resistance, making it an ideal choice for precision machined parts in demanding applications.

Types of Aluminum Materials Used for Precision Machined Parts

SYM Precision Machining works with a variety of aluminum alloys, each selected based on the requirements of the project. These alloys offer unique properties suited for different applications, ensuring the final product performs optimally.

AL6061

One of the most commonly used aluminum alloys due to its excellent strength-to-weight ratio, corrosion resistance, and good machinability. It is widely used in industries such as aerospace, automotive.

AL7075

Known for its high strength, AL7075 is a high-performance alloy used in aerospace, military, and other applications where strength is a priority. It’s ideal for components that experience high stress.

AL5083

This alloy is known for its excellent resistance to marine environments, making it a preferred choice for marine and offshore applications. It’s also commonly used in shipbuilding, aluminum tanks, and pressure vessels.

AL6082

A versatile alloy that combines strength and corrosion resistance, AL6082 is ideal for structural components in construction, engineering, and heavy-duty machinery.

AL5052

With excellent corrosion resistance, especially in marine environments, AL5052 is often used for marine equipment, fuel tanks, and chemical equipment.

Surface Finishes for Aluminum Machined Parts

Aluminum parts often require surface treatments to enhance their appearance, durability, and functionality. At SYM, we offer a variety of surface finishes for aluminum machined parts

Anodizing

One of the most common surface treatments for aluminum. It increases corrosion resistance and surface hardness while providing a decorative finish. Anodizing also allows for the addition of colors.

Powder Coating

Powder coating offers a tough, durable finish that is resistant to scratches, fading, and corrosion. It’s ideal for aluminum parts used in outdoor applications or environments with high wear.

Polishing

For parts that require a smooth and shiny finish, polishing is an ideal choice. It enhances the appearance of the parts while providing a smooth, reflective surface.

Sandblasting

This process creates a matte or textured finish by blasting the part with fine particles. It’s often used for industrial or functional parts that require a non-glossy finish.

Hard Coat Anodizing

A more durable form of anodizing, hard coat anodizing is used for high-wear applications where increased wear resistance and strength are required.

Applications of Aluminum Machined Parts

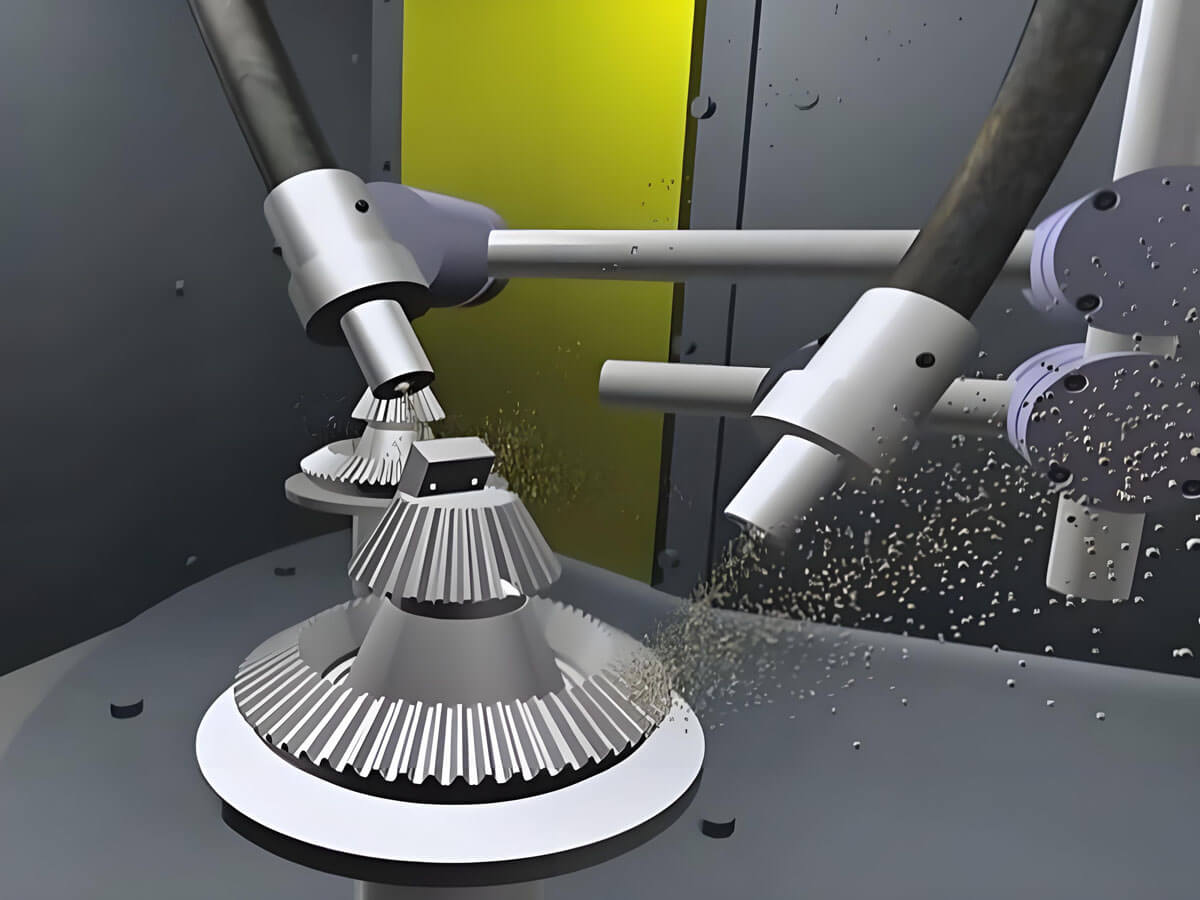

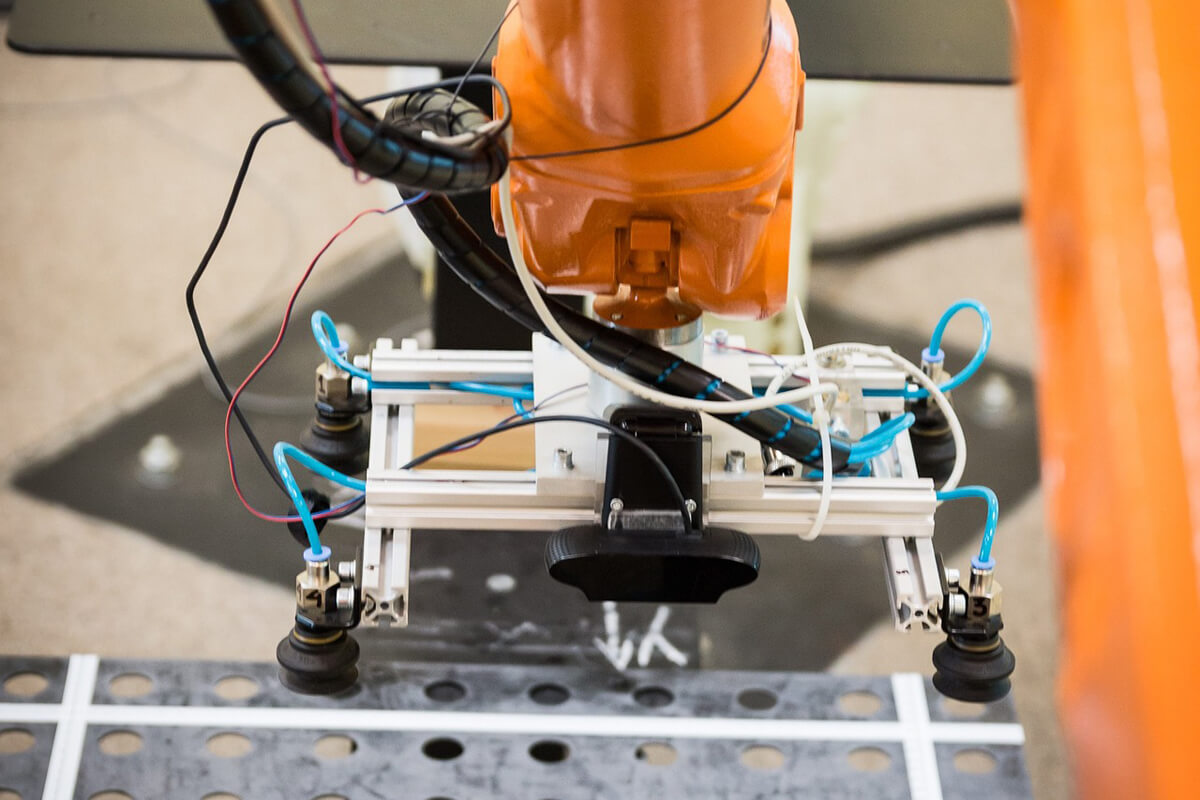

Flexible Robots and Automation Equipment

Aluminum is a go-to material for building lightweight yet durable robotic components. Our precision machined aluminum parts are used in flexible robots, robotic arms, and automation systems where reducing weight without compromising strength is crucial. These parts may include mounting brackets, frames, gears, and sensor housings.

Aerospace Industry

Aluminum alloys like AL6061-T6 and AL7075 are widely used in the aerospace industry for their strength, lightweight properties, and excellent corrosion resistance. SYM’s precision machined parts are used in aircraft structures, engine components, landing gear, and aerospace accessories, where exacting tolerances and performance reliability are .

Automotive Industry

Lightweight aluminum parts are essential for improving fuel efficiency in vehicles without sacrificing strength. SYM provides precision aluminum parts for automotive engines, chassis, brackets, transmission components, and heat exchangers, among other automotive applications.

Medical Devices and Equipment

In the medical industry, precision aluminum parts are used for surgical instruments, medical implants, and diagnostic equipment, where high performance, biocompatibility, and precise dimensions are essential for patient safety and equipment functionality.

Consumer Electronics

Aluminum’s lightweight and corrosion-resistant properties make it an excellent choice for parts in smartphones, laptops, and wearable devices. SYM provides machined parts such as enclosures, mounting brackets, connectors, and heat sinks that are critical for device performance and longevity.

Marine Industry

Aluminum alloys like AL5083 are specifically used for parts exposed to harsh marine environments. From boat hulls to marine equipment and offshore structures, SYM provides machined aluminum parts that stand up to saltwater corrosion and the mechanical demands of the marine industry.

Surface finishing is crucial for enhancing the appearance, durability, and functionality of machined parts. SYM offers a variety of surface finishes to meet the specific requirements of each project

Why Choose us for Your Aluminum Parts?

25+ Years of Expertise

With over two decades of experience in the machining industry, SYM understands the complexities of working with aluminum and how to optimize material properties to deliver the best results.

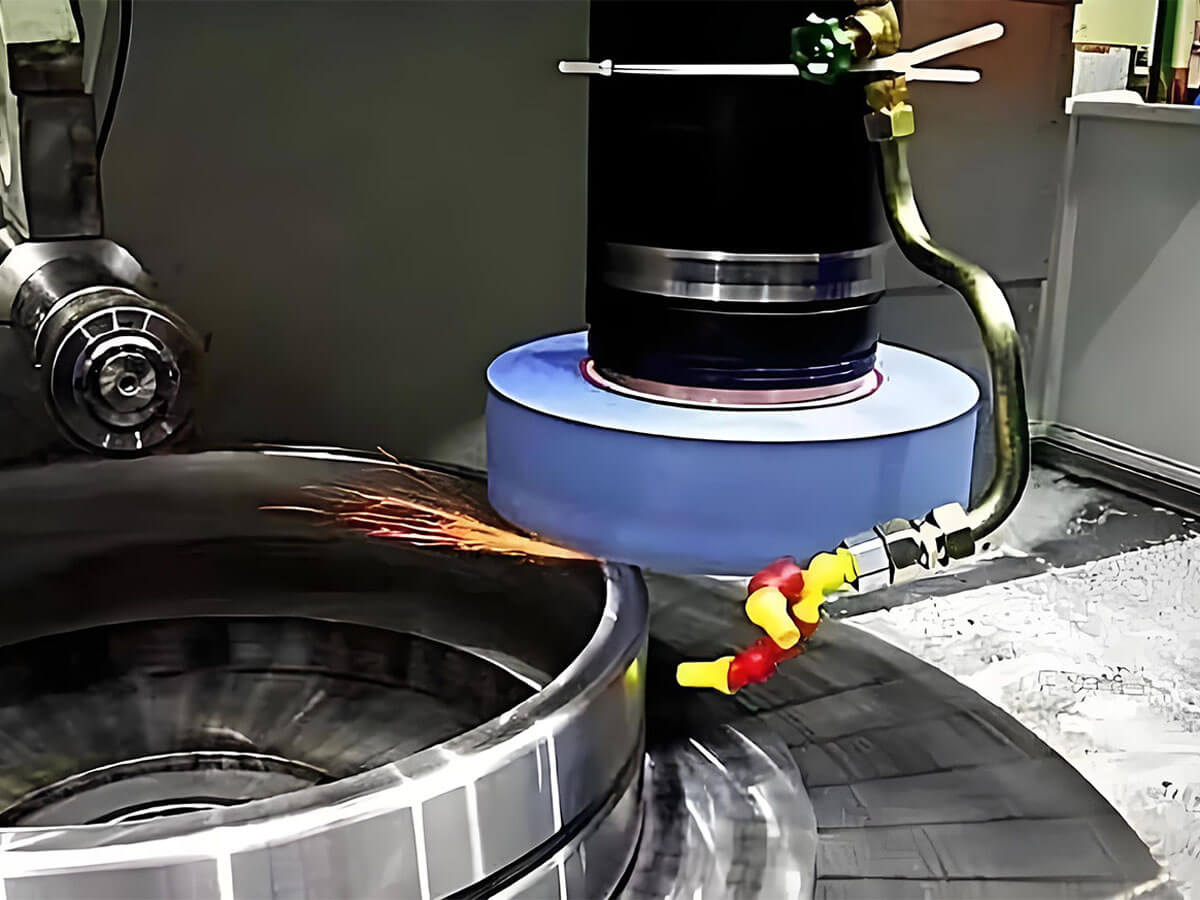

State-of-the-Art Equipment

Our advanced CNC machines, coupled with high-precision measuring tools, ensure that every aluminum part is produced to the exact specifications, meeting even the tightest tolerances.

Wide Range of Services

From CNC turning and milling to EDM and grinding, we offer a full suite of machining services to cater to every requirement. Additionally, we provide various surface finishes to enhance both the functionality and appearance of aluminum parts.

No MOQ

Whether you need a single prototype or thousands of units, SYM can handle orders of any size with the same level of care and precision.

Global Reach with On-Time Delivery

SYM serves customers worldwide, ensuring timely delivery of high-quality precision parts, no matter where you are located.