What is EDM machining?

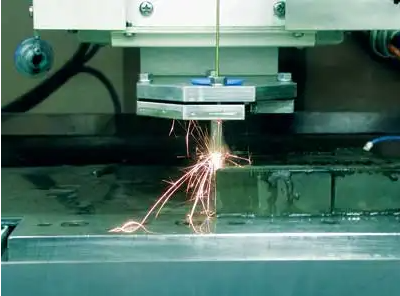

Electrical Discharge Machining (EDM), the continuous moving thin metal wire (called electrode wire) to perform pulse spark discharge on the workpiece to remove metal, cut and shape.

EDM is suitable for processing high hardness conductive workpieces. Processing various complex and precise small workpieces, such as punches,concave dies,fixed plates,etc. EDM also process various micro holes and grooves, narrow slits, arbitrary curves, etc.

The advantages:

- Small machining allowance

- High machining accuracy

- Short production cycle

- Low manufacturing cost

EDM machining speed and surface quality:

There are three grade processing methods, rough, medium and fine grade.

Rough machining is realized with high power and low loss, while the medium and precise machining, the electrodes have relatively large losses, but in general,the allowances for medium and precise machining is small, so electrode loss is also extremely small.

The accuracy is +0.01mm, surface roughness is Ra3.2~6.3um.

Material:

The electrodes are made of materials such as copper, graphite and tungsten, which can easily conduct electricity.

EDM machining is suitable for some metal machining parts. Such as carbon steel, stainless steel, tool steel, copper alloy and aluminum alloy.

EDM carbon slag and slag discharge

EDM processing can be carried out smoothly under the condition that carbon slag is generated and carbon slag is excluded.