Electroplating Services

Home » Surface Finishing Services » Electroplating Services

Getting a quote for Electroplating Services, we can customize any option for you.

Discover the best metal parts with high quality electroplating service. Complete variety and excellent appearance. Include nickel plating, chrome plating, zinc plating, black oxide and E-coating, etc.

Types of Electroplating Services

Chrome Plating

Offers extreme hardness and a mirror-like finish.

- Hard chrome plating: Provides extreme hardness and wear resistance, often used for industrial applications.

- Decorative chrome plating: Offers a bright, mirror-like finish, commonly used for aesthetic purposes

- Trivalent chrome plating: A more environmentally friendly alternative to hexavalent chrome plating.

- Micro-porous chrome plating: Provides improved corrosion resistance by allowing a thin layer of nickel to show through.

- Black chrome plating: Produces a dark, decorative finish with good corrosion resistance.

Nickel plating

Nickel plating is a popular surface finish for its durability, corrosion resistance, and attractive appearance.

- Nickel plating is often known for its bright, mirror-like finish, which can look similar to chrome but with a slightly warmer tone. This reflective finish makes it popular for decorative applications, such as in automotive trim, household fixtures, and jewelry.

- Nickel plating can also be achieved with a satin or matte finish, offering a more subdued look compared to the bright, reflective version. Satin nickel has a soft, smooth appearance and a modern look, commonly used in interior design, kitchen hardware, and lighting fixtures.

- Compared to chrome, nickel plating has a very subtle yellowish or gold tint, which gives it a warmer appearance. This characteristic makes it ideal for applications where a softer or less stark look is desired.

Zinc Plating

Provides excellent corrosion protection, often used on steel.

- Clear zinc: Provides a bright, silver-like finish

- Yellow zinc: Offers a gold-like appearance, often used for decorative purposes

- Black zinc: Creates a dark, matte finish with good corrosion resistance

- Green zinc: Produces an olive-drab color, commonly used in military applications

- Blue zinc: Results in a blue-tinted finish, sometimes used for aesthetic purposes

- Copper plating: Used as a base layer for other plating or for electrical conductivity

- Gold plating: Offers excellent conductivity and corrosion resistance, used in electronics

- Silver plating: Provides high electrical conductivity and a lustrous appearance

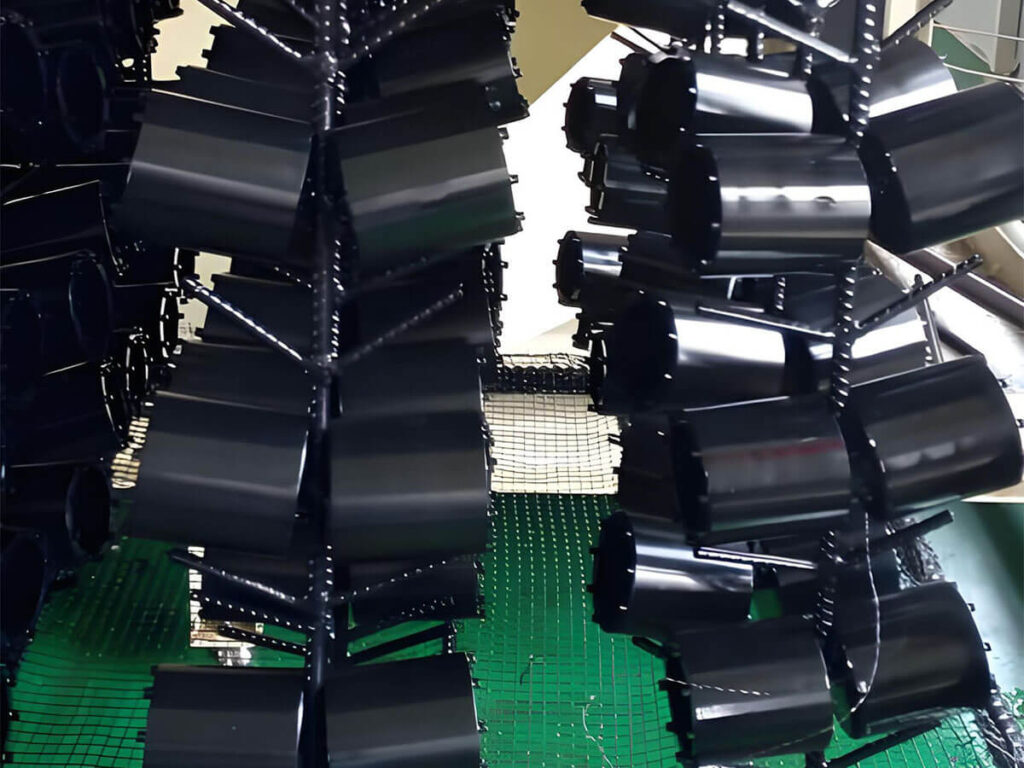

Black Oxide

- Creates a black finish on ferrous metals

- Provides moderate corrosion resistance

- Often used for decorative purposes and to reduce light reflection

Electro-coating (E-coating)

- Provides excellent corrosion resistance and uniformity

- Environmentally friendly process with high transfer efficiency

- Commonly used in automotive and appliance industries

Electroplating Certificates

SYM’s electroplating services are fully compliant with both RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. This compliance ensures that their plating processes meet stringent environmental and safety standards, making them suitable for industries requiring adherence to these directives.

RoHS

RoHS compliance involves restricting the use of specific hazardous materials in electrical and electronic equipment, such as lead, mercury, cadmium, hexavalent chromium, and certain flame retardants. By adhering to RoHS standards, SYM ensures that their electroplating services do not introduce these harmful substances into products, aligning with global environmental initiatives.

REACH

REACH compliance requires the registration and evaluation of chemicals used within the European Union to ensure they do not adversely affect human health or the environment. SYM's commitment to REACH standards indicates that they have thoroughly assessed and managed the chemicals involved in their electroplating processes, ensuring safety and sustainability.

What material is suitable for electroplating?

Electroplating services can be applied to a range of materials, but certain metals and conductive materials are particularly well-suited for achieving quality, durable finishes. Metals Commonly Used for Electroplating.

Steel

Steel is widely used in electroplating, especially in automotive, industrial, and construction applications. Electroplating can improve steel’s corrosion resistance, hardness, and appearance.

Copper

Copper is commonly electroplated for both decorative and functional purposes. It’s often used as an undercoat to enhance adhesion for other metal layers, like nickel or gold, due to its excellent conductivity and smooth finish.

Brass

Brass, an alloy of copper and zinc, is electroplated to improve appearance and corrosion resistance. It’s popular for decorative applications and hardware, often plated with nickel or chrome for durability.

Zinc

Zinc is commonly electroplated for corrosion resistance in industries like automotive and construction. Galvanized steel is a classic example, where zinc electroplating protects steel from rusting.

Aluminum

Although challenging to electroplate due to its oxide layer, aluminum can be plated with a special pre-treatment to make it receptive to plating. Common applications include automotive and aerospace components.

Nickel

Nickel is both a commonly plated metal and a base for additional coatings. It provides corrosion resistance, enhances wear, and offers a smooth, reflective finish, making it popular in decorative applications and electronics.

Stainless Steel

Stainless steel can also be electroplated, though it requires careful surface preparation. It’s often plated with chromium or nickel to further enhance corrosion resistance or improve aesthetics.

Get Your Parts Into Production Today!

Want to learn more about SYM precision machining services, please contact us now.