manual machining service

Home » CNC Machining Services » Manual Machining Services

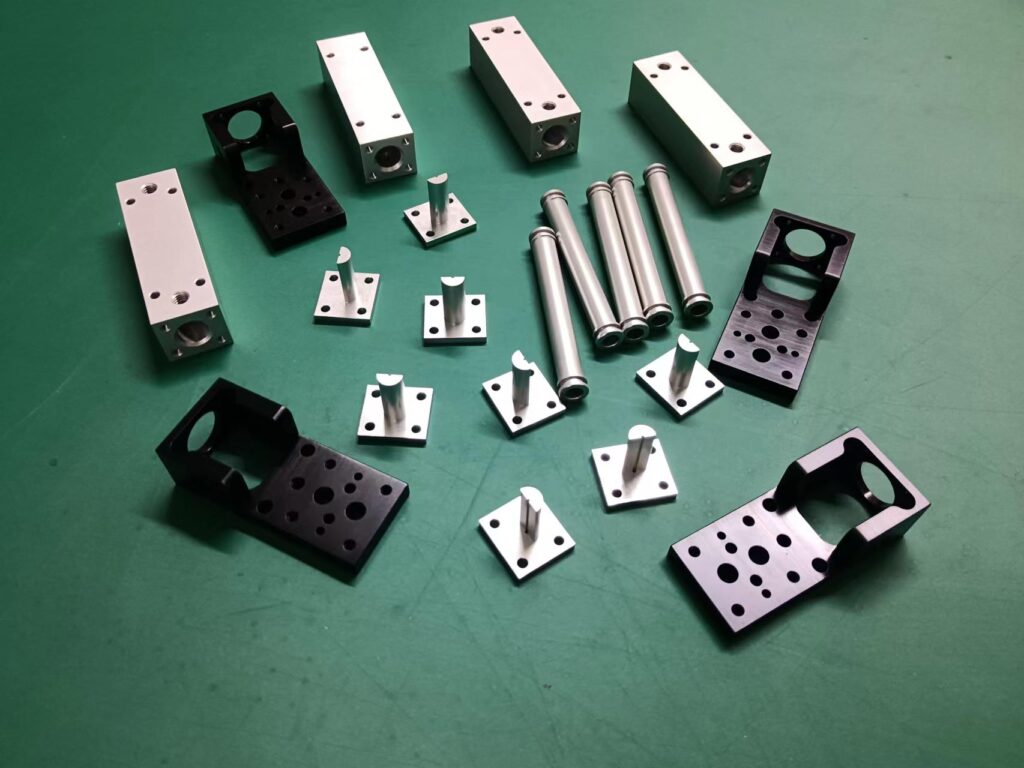

Your Partner for Complete Machining Solutions, manual Machining to Complement CNC Capabilities.

At SYM Precision Machining, we not only excel in advanced CNC machining but also maintain a robust set of manual machining equipment to meet diverse and customized machining needs. We have 52 set of manual machines, including manual surface grinder, milling machine, and lathe, work seamlessly alongside our CNC machining centers to provide comprehensive manufacturing solutions.

Our Manual Machining Capabilities

Manual Surface Grinding Services

- Ideal for achieving flat, smooth surfaces with precision.

- Commonly used for fine-tuning or preparing parts for further CNC machining.

Manual Milling Services

- Flexible and cost-effective for rough machining or small-volume production.

- Suited for parts that require simple cuts or adjustments.

Manual Turning services:

- Perfect for turning, facing, and threading tasks, especially for small batches or prototypes.

- Enables quick modifications or repairs on-the-fly.

SYM Manual Machining Services Capacity

There are 52 set of manual machining equipment at SYM machining factory.

| M/C Type | Qty’ | Brand | Made in | Model | X/Y/Z Travel (mm) | Accuracy (mm) |

| Manual Surface Grinder (17) | 13 | HYFAIR | TAIWAN | HF-618 | 400 X 150 X 250 | 0.002 |

| 4 | SEEDTEC | TAIWAN | 618S | 400 X 150 X 250 | 0.002 | |

| Manual Milling Machine | 28 | GENTIGER | TAIWAN | SHCM-97VS | 650 X 350 X 360 | 0.01 |

| Manual Lathe (7) | 6 | NANFANG LATHE | CHINA | C6132D | Φ350 X 750 | 0.01 |

| 1 | DALIAN MACHINE | CHINA | CDS6150B | Φ500 X 1000 | 0.01 |

Why Combine Manual and CNC Machining?

Given the high size and surface accuracy of parts after precision grinding, proper packaging is crucial to protect these components during storage and transportation.

Efficient Workflow

Manual machines handle rough or preparatory machining, allowing CNC machines to focus on precision and finishing.

Cost-Effective

Reduces unnecessary use of advanced CNC equipment for simpler tasks, optimizing production costs.

Flexibility

Supports quick changes, small-batch production, and custom adjustments.

Versatility

Enhances the ability to work on complex projects requiring multiple machining processes.

How SYM Supports Your Customized Machining Needs

At SYM, we combine the best of both worlds: advanced CNC technology and skilled manual machining.

Meet diverse customer demands, from prototypes to high-volume production.

Provide tailored solutions for unique machining challenges.

Optimize production efficiency while maintaining tight quality control.

Contact SYM today to discuss how our comprehensive machining capabilities can support your next project.

With a balanced integration of 52 manual machines and hundreds of CNC systems, SYM Precision Machining is your one-stop shop for customized, high-quality machined parts. Whether it’s rough machining, fine-tuning, or complex precision work, we have the equipment and expertise to deliver on your requirements.