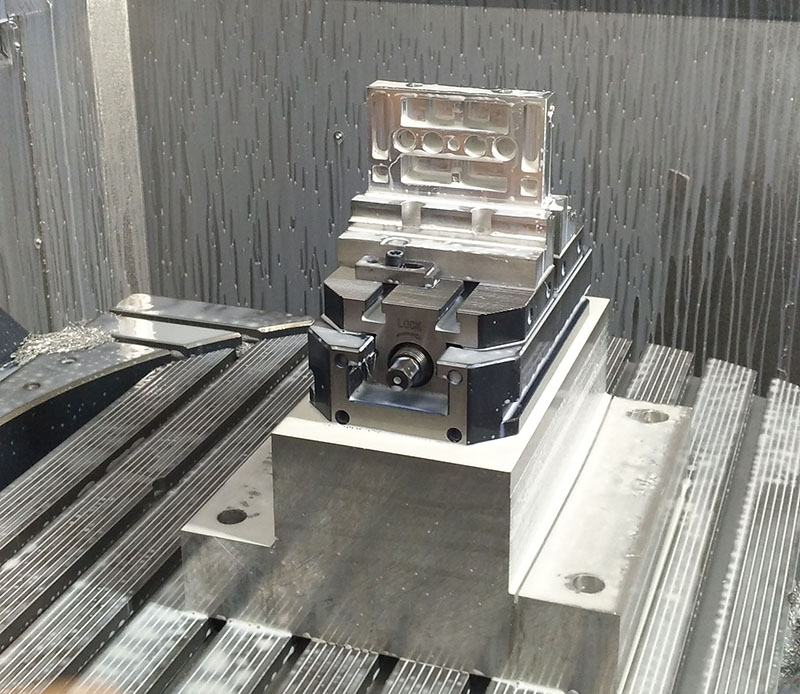

Custom fixtures machining services

Home » Mechanical Assembly Services » Custom Fixturing Machining Services

The best custom machining service in China.

Getting top-quality customized machined part for your fixtures and clamps.

Custom Fixtures and Clamps: Involves designing and creating specialized tools to hold components securely during assembly, ensuring precise alignment and stability.

Comprehensive custom machining capabilities

Milling Processing

Advanced milling operations for creating complex geometries and surface features.

Turning Processing

Precision CNC turning for cylindrical parts and complex profiles.

Grinding Processing

High-precision grinding for achieving superior surface finishes and tight tolerances.

EDM (Electrical Discharge Machining)

Specialized machining for intricate shapes and hard materials.

Fitter Assembly

Skilled technicians for precise assembly of complex fixtures and components.

Our one-stop custom machining services allows us to efficiently manufacture a wide variety of fixture components, ensuring high quality and consistency across different manufacturing technologies. This comprehensive capability enables us to meet diverse product requirements and deliver complete solutions to our clients.

Custom Machining Process for Fixtures and Clamps

At SYM precision machining, we follow a rigorous custom machining process for fixtures and clamps:

Part Drawing Analysis

We carefully analyze each part drawing to understand the specific requirements and specifications.

Tolerance Control

We strictly control tolerances during the machining process, with special attention to critical dimensions.

Individual Part Machining

Each part is machined according to its specific drawing, ensuring precision and accuracy.

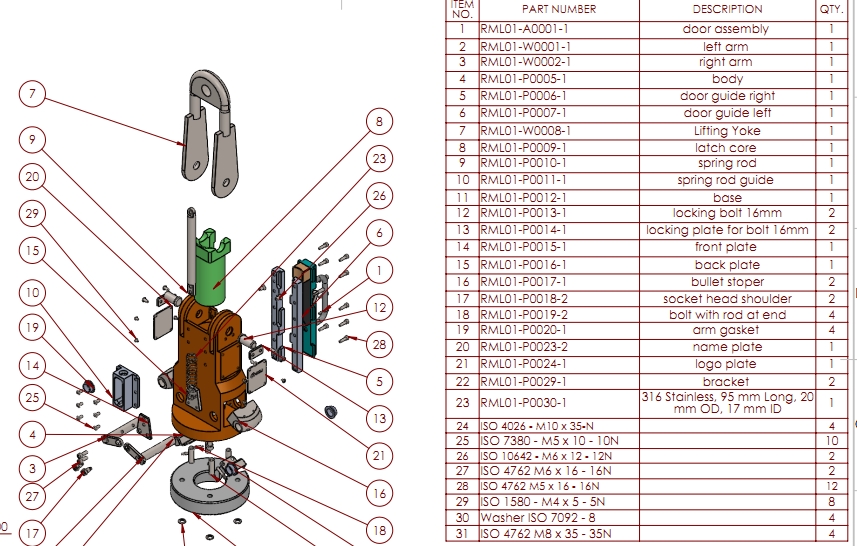

Assembly Preparation

We refer to the general assembly drawing and BOM (Bill of Materials) table to prepare for the assembly process.

Assembly Process

Following the assembly drawing guidelines, we carefully assemble all parts together to create the final fixture or clamp.

Quality Assurance

Each step of the process undergoes thorough quality checks to ensure compliance with specifications and overall functionality.

Importance of BOM form in Assembly of Fixtures and Clamps

Accurate Component Listing

A well-prepared BOM ensures that all necessary parts for the fixture or clamp are accounted for, reducing the risk of missing components during assembly.

Streamlined Procurement

With detailed part information, including specifications and quantities, the BOM facilitates efficient ordering and inventory management.

Assembly Guidance

The BOM serves as a reference guide during the assembly process, helping technicians identify and use the correct components.

Quality Control

By listing exact specifications, the BOM aids in quality checks, ensuring that the correct parts are used and assembled properly.

Cost Management

A comprehensive BOM allows for accurate cost estimation and control throughout the production process.

In the context of fixtures and clamps, where precision and functionality are paramount, a detailed and accurate BOM is essential for ensuring that the final assembly meets all design specifications and performance requirements.

A comprehensive BOM form might include

- 1. Part Description: A clear, descriptive name for each component.

- 2. Drawing Number: A unique identifier for the part's technical drawing.

- 3. Quantity: The number of each part required for the assembly.

- 4. Material: The specific material each part is made from.

Additionally, for standard parts, the BOM form should also include information to ensure accurate identification and sourcing.

- 1. Brand : The manufacturer or brand name of the standard part.

- 2. Part Name: A clear, descriptive name of the standard component.

- 3. Model Number: The specific model or catalog number assigned by the manufacturer.

Including these details in the BOM for standard parts helps in:

- Ensuring the correct part is ordered and used in the assembly

- Facilitating easier replacement or reordering of parts

- Maintaining consistency in part selection across different projects or production runs

This level of detail is particularly important for critical components where exact specifications and performance characteristics are crucial to the overall functionality and quality of the assembled product.

Get Your Parts Into Production Today!

Want to learn more about SYM precision machining services, please contact us now.