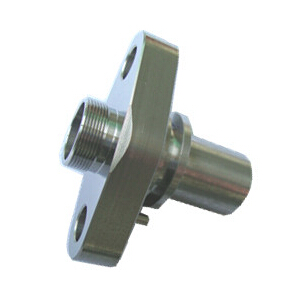

How to obtain high quality machined parts ?

If you want to obtain high quality machined parts,the key point is material.there are 3 simple ways to identify the stainless steel.

1.Magnetic test

The magnetic test is the easiest way to distinguish annealing austenitic stainless steel and ferritic stainless steels.  austenitic stainless steel is Non-magnetic steel, but by the large reduction will have a mild cold magnetism. Pure chromium steel and low alloy steels are ferromagnetic steel.

austenitic stainless steel is Non-magnetic steel, but by the large reduction will have a mild cold magnetism. Pure chromium steel and low alloy steels are ferromagnetic steel.

2.Point nitric acid test

The concentrated nitric acid and dilute nitric acid has inherent corrosion resistance. This performance so that it can easily be distinguished from most other metals or alloys. However, if the high quality machined parts made from SS420 and 440C, points during the test is slightly corrosive nitric acid, concentrated nitric acid immediately encountered nonferrous metals will corrode. The dilute nitric acid having a strong corrosive to carbon steel.

3.Copper sulfate point test

Copper sulfate point test is the easiest way to quickly distinguish between normal carbon steel and stainless steel of all types. The concentration of copper sulfate solution used is 5 ~10, before testing, inspection area should be completely clear, and polish a small area, then drip copper sulfuric solution to the clean area. Ordinary carbon steel or iron in a few seconds the surface of the metal to form a layer of copper, and stainless steel surfaces will not produce copper precipitation or display color.