Looking for high-quality prototype machined parts? Discover the benefits, materials, machining processes, and industries that rely on precision prototype machining.

Einführung

Prototype machined parts are crucial in modern manufacturing, allowing businesses to test designs before full-scale production. Whether in aerospace, automotive, or medical industries, these precision-machined components enable engineers to refine product designs, improve functionality, and ensure manufacturability.

But what makes prototype machining so essential, and how does it work? This guide explores everything you need to know about prototype machined parts.

What Are Prototype Machined Parts

Prototype machined parts are custom-made components created in small quantities to test a design before mass production. These parts help engineers validate product performance, functionality, and fit. Unlike production parts, prototypes allow modifications and adjustments without significant financial investment.

Why Are They Important?

Design Validation: Ensures the part meets functional and dimensional requirements.

Cost Efficiency: Detects flaws early, reducing expensive errors in mass production.

Faster Time-to-Market: Speeds up product development and reduces lead times.

Material Testing: Allows testing of different materials for optimal performance.

Advantages of Prototype Machining Services

Prototype machining offers several benefits over traditional prototyping methods like 3D printing and casting:

1. High Precision

CNC machining ensures tight tolerances, making prototype parts highly accurate.

2. Versatility

Supports a wide range of materials, from metals to engineering plastics.

3. Quick Turnaround

CNC machining can produce prototypes in days compared to weeks required for molds.

4. Cost-Effective for Small Batches

No expensive tooling required, making it ideal for low-volume production.

Common Materials for Prototype Machined Parts

The choice of material depends on the application and required properties:

Metals:

| Material | Properties |

| Aluminum (6061, 7075) | Lightweight, corrosion-resistant, strong |

| Stainless Steel (304, 316) | High strength, wear-resistant, good for harsh environments |

| Titanium (Grade 2, Grade 5) | Excellent strength-to-weight ratio, biocompatible |

| Brass & Copper | Great electrical conductivity, corrosion resistance |

Plastics:

| Material | Properties |

| POM (Delrin) | High stiffness, low friction |

| PEEK | High-temperature resistance, excellent mechanical properties |

| ABS | Good impact resistance, cost-effective |

| PTFE (Teflon) | Chemical resistance, low friction |

Key CNC Machining Processes for Prototyping

Several machining techniques are used to manufacture prototype parts:

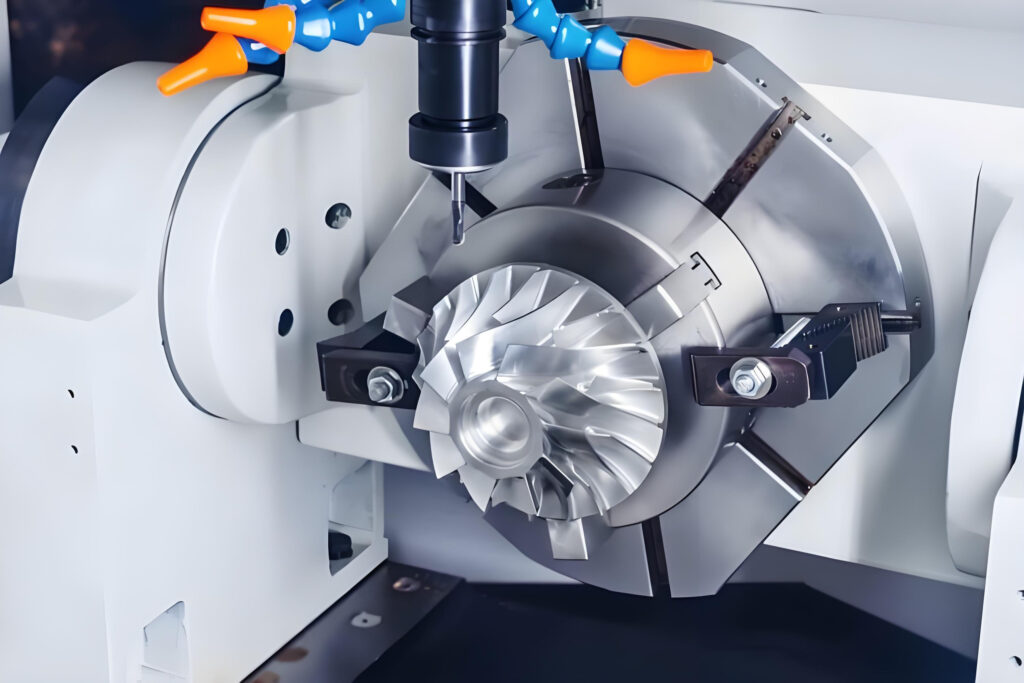

1. CNC Milling

Uses rotating cutting tools to remove material from a solid block, ideal for complex geometries.

2. CNC Turning

A lathe rotates the material while a cutting tool shapes it, suitable for cylindrical parts.

3. Electrical Discharge Machining (EDM)

Uses electrical sparks to cut metal, perfect for intricate shapes and hardened materials.

4.3D Printing vs. CNC Machining

While 3D printing is great for rapid prototyping, CNC machining offers superior strength, accuracy, and material choices.

Surface Finishes for Prototype Parts

The right surface finish enhances performance and aesthetics:

- Anodizing: Improves corrosion resistance and appearance.

- Powder Coating: Provides a durable, colorful finish.

- Polishing: Creates a smooth, reflective surface.

- Bead Blasting: Gives a uniform matte finish.

- Electroplating: Adds a thin metal layer for extra durability.

Challenges in Prototype Machining

Manufacturing prototype parts comes with its own set of challenges:

- Achieving Tight Tolerances: Small deviations can impact functionality.

- Material Selection: Choosing the right material for strength, durability, and cost.

- Cost Control: Prototyping can be expensive without the right strategy.

- Lead Time Management: Balancing speed and precision.

Industries That Rely on Prototype Machining

Several industries depend on prototype machining to refine their products:

| Industrie | Anmeldung |

| Luft- und Raumfahrt | Aircraft components, turbine parts |

| Automobilindustrie | Engine parts, transmission components |

| Medizinische | Surgical instruments, implants |

| Robotics | Precision gears, structural parts |

| Unterhaltungselektronik | Housings, connectors, PCB enclosures |

Choosing the Right Prototype Machining Partner

Selecting the right manufacturer ensures quality and efficiency:

1. Experience & Expertise: Look for a company with extensive experience in CNC machining.

2. Certifications & Quality Control: ISO 9001, AS9100, and IATF 16949 certifications indicate high-quality standards.

3. Advanced Equipment: A manufacturer with 5-axis CNC machines and EDM capabilities can handle complex designs.

4. Fast Lead Times: A good supplier should deliver prototypes within days, not weeks.

5. Customer Support: Excellent communication ensures smooth project execution.

Sheng yuan Precision Machining stands out as a trusted partner for prototype machining needs. With over 25 years of experience, SYM has developed a strong reputation for delivering high-quality precision parts across a wide range of industries.

Here’s why SYM is the perfect fit for your next prototype project:

Expertise in Diverse Materials:

SYM has extensive knowledge and expertise in machining a wide variety of materials used in prototype manufacturing. From metals like aluminum, stainless steel, and titanium to plastics such as POM and PTFE.

SYM offers unmatched flexibility in working with different types of materials. This allows them to meet the unique demands of each project, regardless of material complexity.

Advanced Technology & Equipment:

With over 470 skilled staff members and state-of-the-art equipment, including CNC lathes, milling machines, EDM, and manual machining tools, SYM is equipped to tackle even the most complex machining tasks. Their cutting-edge technology ensures precise tolerances, high-quality finishes, and faster production times, making them a go-to choice for prototype parts.

No MOQ (Minimum Order Quantity):

Unlike many other manufacturers, SYM Precision Machining offers flexibility by not requiring a minimum order quantity. Whether you need just one prototype or hundreds of parts, SYM can accommodate your order, ensuring that even small-batch production can be handled efficiently without compromising on quality.

Quality Control & Assurance:

Quality is at the forefront of SYM’s operations. They follow stringent quality control processes, ensuring each part undergoes thorough inspection and testing.

Their certifications in ISO 9001, AS9100D, IATF16949, and other industry standards reflect their commitment to maintaining high-quality production standards, making SYM a reliable supplier for prototype parts.

Fast Lead Times & Timely Delivery:

SYM understands the importance of speed in prototype development. Their efficient production processes and in-house capabilities enable them to provide fast turnarounds, allowing customers to meet tight deadlines. They are dedicated to delivering parts on time, ensuring that your project stays on track.

Strong Customer Support:

SYM’s customer service team is committed to providing the best possible support throughout the prototype process. From initial consultation to final delivery, their team works closely with clients, providing expert advice, technical assistance, and proactive communication to ensure the project’s success.

When you choose SYM Precision Machining, you’re partnering with a company that not only delivers high-quality prototype parts but also supports your project from start to finish with expert guidance, advanced capabilities, and unwavering commitment to customer satisfaction.

FAQs on Prototype Machined Parts

How much does prototype machining cost?

— The cost depends on material, complexity, quantity, and surface finish. CNC prototypes range from $50 to several hundred dollars per part.

What is the typical lead time for prototype parts?

— Most CNC machining services deliver prototypes within 3-7 days, depending on design complexity.

Can CNC machining handle intricate designs?

— Yes, 5-axis CNC machines can produce highly complex geometries with tight tolerances.

Which is better: CNC machining or 3D printing for prototyping?

— CNC machining offers better strength, precision, and material options, while 3D printing is faster for concept models.

What tolerances can be achieved in prototype machining?

— Most CNC machined prototypes achieve tolerances as tight as ±0.0004″.

Can I request multiple finishes for a single prototype part?

— Yes, different areas of a part can have different finishes, such as anodizing and bead blasting.

Schlussfolgerung

Prototype machined parts play a vital role in modern manufacturing, allowing companies to refine designs and accelerate product development. With precision CNC machining, businesses can produce high-quality prototypes in various materials with exceptional accuracy.

Whether you’re in aerospace, automotive, or medical industries, choosing the right machining partner ensures your prototypes meet the highest standards.

Ready to bring your design to life? Start your prototype machining project heute!