Quality assurance of precision machining

You must been known the quality assurance of precision machining is very important.the advanced measuring equipment is helpful for quality assurance. In automobile industry, auto parts are characterized by high quality, large batch and different shapes.This also enables us to pay more attention to the precision machining production and the quality of products. In modern […]

How to reduce the distortion of Delrin Machined Parts during processing?

POM/ Delrin. Thermoplastic crystalline polymer,it is known as ‘super steel’,with high mechanical strength and rigidity,strong impact resistance,used for widely temperature range (-40℃~120℃). At present,the Delrin as lower cost of plastic,It is replacing some of the markets that have traditionally been dominated by metals.For examples,alternative zinc alloy, brass, aluminum and steel parts.Has been widely used in […]

Analysis and design of cnc machining process for complex parts

CNC Machining Process for Complex Parts Complex parts are the most common processing products in CNC machining process. Its processing route will be covered, Including selection processing methods, division of processing stage, division process, processing sequence arrangement and determination of the processing route and so on. 1. Determination of parts blank According to the parts process design, […]

Grinding Process

What is grinding process? Grinding process is also known as grinding machining. Grinding is machining the surface of metal parts by grinding wheel,oil stone and abrasive. The machine tool that uses grinding wheel is usually called grinding machine,the machine tool that uses oil stone and abrasive is called precise grinding machine. The grinding wheel is […]

Learning details of precision machining project from customers

Summary of April and May, although a bit tired,but also a lot of gains.SYM interviewed a lot of foreign customers.Israeli customer Mr.Yaron, American Mr.Scott, Mr.Smith,Mr.Brien and Mr.Borgart. By contacting each customer,we have a better understanding of the customer’s requirements for their precision machining project. The main machining project for Israeli customer is aluminum heatsink. We […]

Tips of Aluminum Welding

Without doubt, the use of aluminum is increasing within the welding fabrication industry. Manufacturers are often adopting this material, either through innovation, or through pressure applied by their end users. Recently some aluminum welding problems have arisen during operation (as seen in the picture). It warns us that we should pay more attention to the […]

High quality machined products for clients

This afternoon, there are many new parts that need finish QA for high quality machined products before shipment. The high quality is put as the first in Sheng Yuan Mechanical Equipment Engineering CO., LTD (SYM) For high quality machined products, there are several sections that need inspector strictly control: 1. IQC: incoming material inspection, including […]

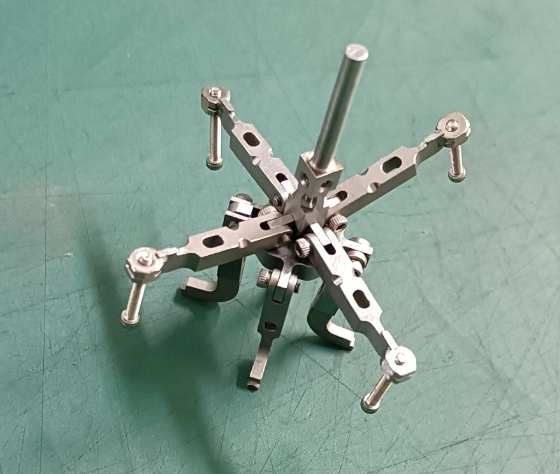

7 kinds of clamping method of turning eccentric parts

In mechanical transmission, the rotary motion into reciprocating linear motion or linear motion into rotary motion, usually with an eccentric shaft or crankshaft to complete.Eccentric shaft that is parallel to the axis of the parts between the cylindrical outer and without overlap. The method of turning eccentric parts,according to different quantity,shape and precision of the machined […]

6 advantages of High-speed cutting in mold processing

Due to mold processing features is single and small batch, complex geometry.thus processing cycle is long, low productivity.In the conventional mold process, finishing crushed hard tooling commonly used EDM and artificial light repair process, spent a lot of time in later processing.Shorten the processing time and reduce production costs is the main goal of the development […]

How to control the quality of metal machined parts

Quality is always key point for metal machined parts,SYM we understand the importance of ensuring the tolerance for our customers. 1. A whole set of quality system As an ISO9001:2008 and TS16949:2009 compliant supplier ,we keep the quality in the mind all the time . For the while ,the employee of SYM insist the standard […]