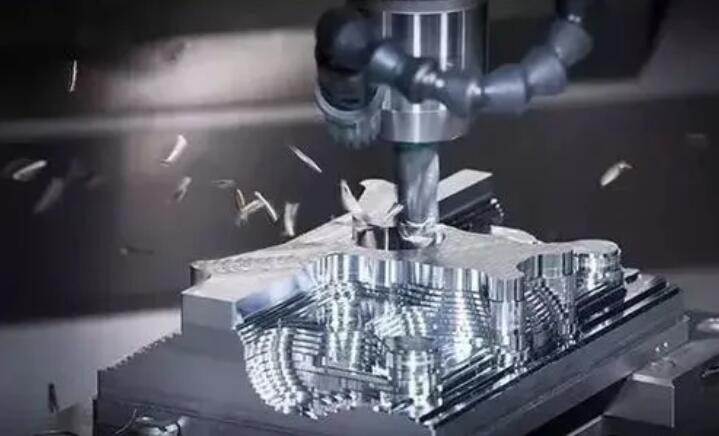

Advanced cnc machining parts factories have lots of cnc machine, they have advanced technologies. They always can produce superior quality machined parts. That’s because they are proficient in the methods and skills of CNC machining.

1. Programming skills

The demand of CNC machining parts is very high.there are two aspects should be fully considered when programming. One is the processing sequence, and the other is parameters such as speed, feed, and depth of cut.

The processing sequence is generally drilling first, then flat end. This can prevent material shrinkage during drilling. Rough machining first, then precise machining. First machining with large tolerances and final machining with small

tolerance.

According to the hardness of the material, choosing a reasonable speed, feed and depth of cut.

- Carbon steel materials: choosing high speed, high feed, and large depth of cut.

- Carbide materials: choosing low speed, low feed, and small depth of cut.

- Titanium alloys materials: choosing low speed, high feed, and small depth of cut.

2.Direct tool setting method

First select the center of the right end of the machined part as the tool setting point, and set it as the zero point. After the machine tool returns to the origin, each tool that needs to be used is set at the zero point.

This direct tool setting method, even if the machining center is powered off, the tool setting value will not be changed after the power is turned on again and restarted.

3.Debugging Tips

In order to prevent errors in the program and mistakes in tool setting, after the parts are programmed, they need to be tested and debugged after the tool is adjusted.

First, carry out simulation processing,and confirm that the program and tool setting are correct.

Second, processing the first part.

Finally,the debugging is over after confirming that the first part is qualified.

4.Tool collision prevention tips

The collision of the tool is a great damage to the accuracy of the equipment. As long as the operator is careful and know methods of anti-collision, collisions can be completely prevented and avoided.

There are only three reasons for tool collision.

1) The input error of the diameter and length of the tool.

2) The input error of dimensions of the machined parts and the initial position of the machined parts.

3) The machined parts coordinate system of the machining center is set incorrectly, or the machine zero point is reset in the machining process.

In order to avoid the collision above, the operator should pay attention more in machining process, observe whether the machine tool has abnormal movement, whether there is spark, whether there is burnt smell. If an abnormal situation is found, the program should be stopped immediately, and start to work after the problem is solved.