Oil and gas industry | Precision components for oil and gas

Home » Industries Served » Oil and Energy Industry

Precision Components Manufacturing for the Oil and Gas Industry

In the demanding world of oil and gas, reliable and durable components are essential to operational success. SYM Precision Machining, with 25 years of experience and expertise, has supported clients in the oil and gas industry by delivering high-quality, customized machined parts that meet the strict requirements of this challenging sector. From precision fixtures and clamps to gas valve blocks, manifolds, and submarine installations, SYM’s CNC machining services help clients secure more projects by delivering parts that meet stringent industry standards.

Materials Used for Precision Components in the Oil and Gas Industry

Oil and gas applications demand materials that can withstand harsh environments, including extreme temperatures, high pressures, and corrosive substances. SYM works with a range of robust materials to meet these demanding conditions:

Stainless Steel (316, 316L, Duplex)

Known for its excellent corrosion resistance and strength, stainless steel is frequently used in components that encounter seawater, high salinity, and acidic conditions.

Inconel and Other Nickel Alloys

Inconel is a superalloy that can withstand high temperatures and corrosion, making it suitable for components in high-pressure, high-temperature applications.

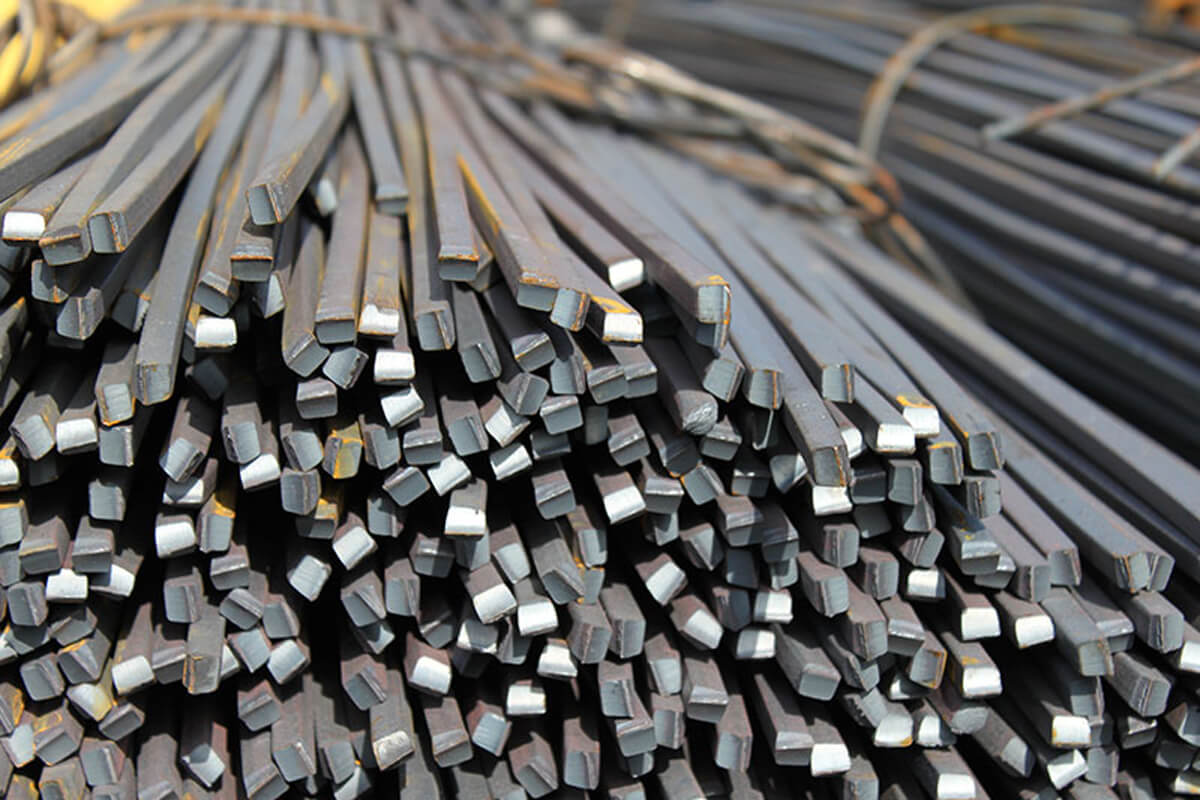

Carbon Steel (e.g., AISI 4130)

Carbon steel is used for parts that need high strength and hardness. It can be treated to improve its resistance to wear, making it ideal for parts that experience heavy use.

Titanium

Lightweight, highly corrosion-resistant, and durable, titanium is often used in components exposed to extreme corrosion, especially in underwater applications.

Aluminum Alloys

Aluminum alloys are lightweight and corrosion-resistant, suitable for components that require weight reduction without compromising strength.

Engineering Plastics

For applications that need insulation or non-conductive properties, engineering plastics like PEEK and PTFE offer resistance to chemical corrosion and high temperatures.

By selecting the appropriate material, SYM ensures that each part can withstand the demanding conditions it will face in oil and gas applications.

Key Factors for Precision Components in the Oil and Gas Industry

Manufacturing components for the oil and gas industry requires a focus on precision, durability, and reliability. Here are some important considerations that SYM addresses to deliver parts that meet the highest standards:

Corrosion Resistance

Oil and gas environments expose components to corrosive elements, such as saltwater, chemicals, and extreme heat. Corrosion-resistant materials and surface treatments are essential to extend the life of these parts.

High-Pressure and High-Temperature Tolerance

Many oil and gas components, such as valves, manifolds, and pressure fittings, operate in high-pressure and high-temperature conditions. SYM ensures each part meets strict tolerance and material standards to perform reliably under these extreme conditions.

Precision and Tolerances

Many components in oil and gas must fit precisely to ensure safety and efficiency. CNC machining at SYM delivers micron-level precision, ensuring each component aligns perfectly with others and maintains tight tolerances for efficient operation.

Surface Finishing

Oil and gas components often require specific surface finishes to enhance corrosion resistance, reduce friction, or improve wear resistance. SYM offers specialized finishes, including anodizing, nickel plating, and electropolishing, to ensure each component can perform well in challenging environments.

Compliance with Industry Standards

Components used in oil and gas must meet industry standards such as NACE, API, and ASTM to ensure safety, reliability, and performance. SYM’s commitment to these standards helps clients trust that each part will perform reliably in critical applications.

Longevity and Wear Resistance

Parts in the oil and gas industry are costly to replace, particularly when located in remote or subsea environments. SYM manufactures durable components that are designed to last, reducing the frequency and cost of replacement.

By selecting the appropriate material, SYM ensures that each part can withstand the demanding conditions it will face in oil and gas applications.

Precision Components SYM Manufactures for Oil and Gas Applications

SYM has manufactured a variety of precision components that serve critical functions in oil and gas operations.

Precision Fixtures and Clamps

These components are used to hold pipelines, equipment, or valves securely in place. Manufactured to high precision, SYM’s fixtures and clamps ensure stability and alignment, reducing the risk of leaks or damage.

Submarine Installation Parts

Parts used in underwater installations need extreme corrosion resistance and robustness. SYM provides machined parts that meet the demands of subsea environments, ensuring durability and functionality in deep-sea applications.

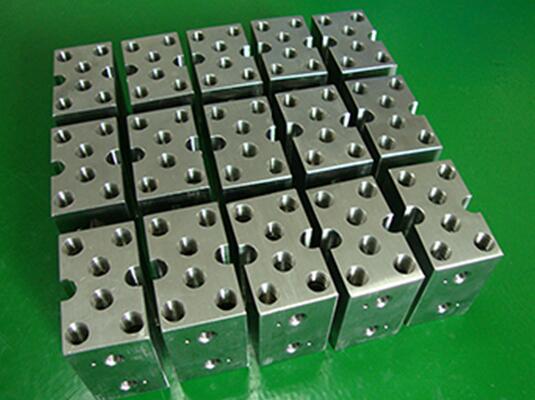

Gas Valve Blocks

Valve blocks are integral to controlling the flow of gas in oil and gas pipelines. SYM’s precise machining and high-quality materials ensure that these components function reliably in high-pressure situations.

Manifolds

Manifolds are used to control fluid distribution in oil and gas systems. SYM produces manifolds with precision-engineered ports and channels to ensure efficient flow and prevent leaks.

High-Pressure Fittings and Connectors

These parts require exacting tolerances to withstand high pressures without leakage. SYM’s CNC machining ensures a tight, secure fit to keep fluids contained even under extreme

Why Choose SYM Precision Machining for Oil and Gas Components?

SYM’s extensive experience in CNC machining for the oil and gas industry ensures clients receive high-quality, reliable components. Here’s why SYM is a trusted partner for oil and gas projects:

Experience and Industry Knowledge

With years of experience serving the oil and gas industry, SYM understands the unique challenges and requirements for components used in this field.

Material Expertise

SYM has the expertise to work with materials that meet the rigorous standards of oil and gas applications, providing components that are corrosion-resistant, durable, and robust.

Custom Solutions

SYM offers tailored solutions, from prototype to full-scale production, allowing clients to get exactly what they need for specific projects.

Compliance and Quality Assurance

SYM adheres to industry standards, providing parts that clients can trust to perform reliably and safely in critical applications.

In the oil and gas industry, the importance of reliable, precision-machined components cannot be overstated. SYM Precision Machining’s dedication to quality, material expertise, and experience make it an ideal partner for companies in this sector. By providing customized, high-quality parts that meet stringent industry standards, SYM helps clients succeed in even the most challenging environments, ensuring each component can withstand the demands of the oil and gas industry.

Get Your Parts Into Production Today!

Want to learn more about SYM precision machining services, please contact us now.