Electronics Industry | Electronic Precision Parts manufacturing

Home » Industries Served » Electronics Industry

Your solution for high-quality electronic precision parts manufacturing from China

SYM Precision Machining: Your Trusted Partner for High-Quality Electronic Precision Parts

In the fast-paced world of electronics, precision and reliability are paramount. Whether it is mobile phone components, computer hardware, or wearable devices, every part must meet stringent quality standards to ensure performance and longevity. SYM Precision Machining is a trusted partner for companies seeking high-quality, precision-machined electronic parts. With advanced manufacturing technology, precision measuring equipment, and a commitment to excellence, SYM ensures that every part we produce meets the exacting requirements of the modern electronics industry.

Highly Specialized Manufacturing Technology and Precision Measuring Equipment

At SYM, we leverage cutting-edge technology and state-of-the-art equipment to produce precision parts for the electronics industry. Our manufacturing capabilities include:

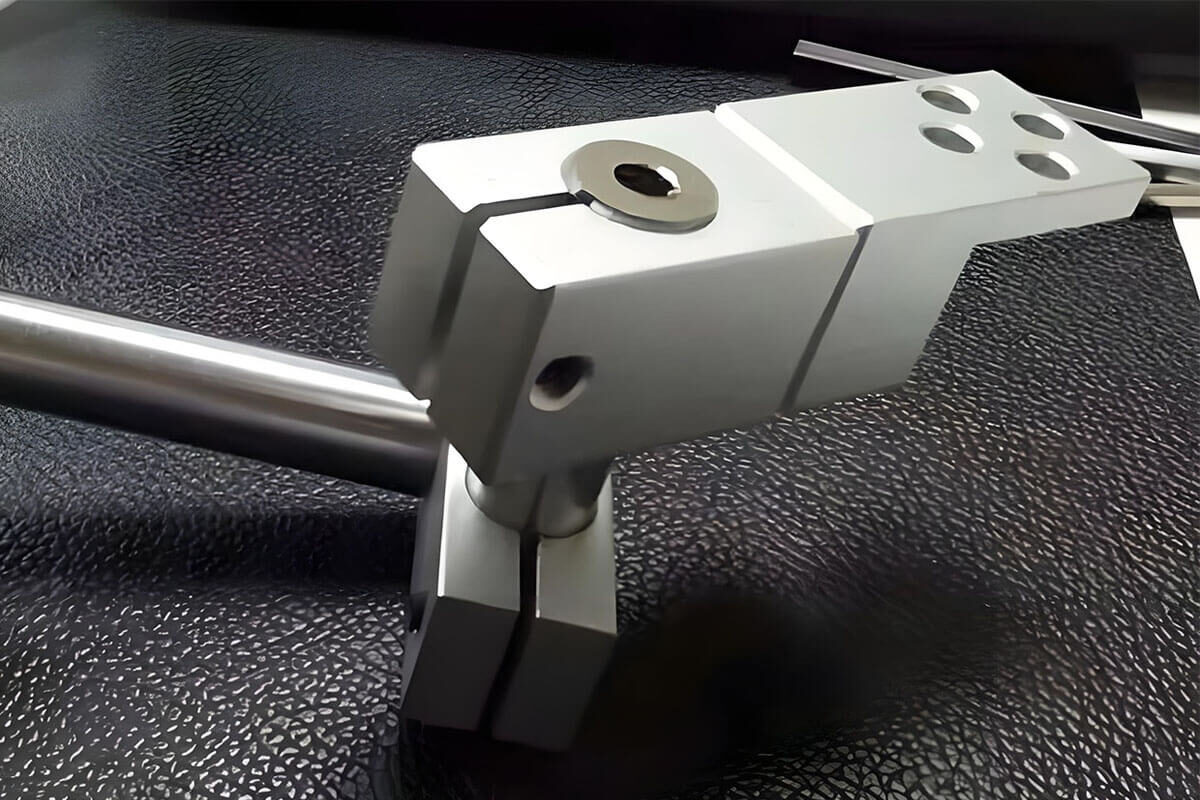

Advanced CNC Machines

With multi-axis CNC machining centers, we can handle complex geometries with tight tolerances, ensuring every part is manufactured to precise specifications.

Precision Measuring Tools

To ensure the highest quality, we utilize advanced measuring equipment, such as Coordinate Measuring Machines (CMM), laser scanners, and optical measurement systems. These tools allow us to verify part dimensions and tolerances with micron-level accuracy, ensuring that each component fits perfectly into the assembly process.

Automation and CAM Software

SYM utilizes the latest Computer-Aided Manufacturing (CAM) software to optimize machining processes, improving efficiency and consistency while reducing production time and costs.

The Role of Precision parts Manufacturing for Electronic Industry

Precision parts manufacturing is a critical technology in the modern electronics industry. It not only ensures the accuracy and reliability of parts but also enables large-scale production and rapid iteration. As consumer electronics continue to evolve, the demand for more complex, miniaturized, and feature-rich components grows. Precision machining provides the tools necessary to meet these demands while maintaining the performance and longevity of the final product.

Key benefits of precision machining in electronics manufacturing include:

Improved Accuracy

Precision machining ensures that electronic parts, such as sensors, connectors, and motors, meet exact dimensional requirements. This improves overall product functionality and ensures the components work seamlessly together.

Increased Reliability

Machining to precise tolerances guarantees that the electronic parts fit together correctly and perform reliably in real-world applications, reducing the risk of product failure.

Efficient Large-Scale Production

With high precision, large batches of electronic parts can be produced efficiently, ensuring consistency and quality across all units.

Rapid Iteration

As electronic devices evolve quickly, manufacturers require fast prototyping and design iterations. Precision machining allows for quick adjustments to designs, enabling faster development cycles and the ability to stay ahead of market demands.

What to Focus on When Designing Electronic Parts

When designing parts for electronic devices, there are several critical factors to consider to ensure that the components perform optimally in the final product:

1. Material Selection

The choice of material plays a key role in the functionality, durability, and performance of electronic parts. Common materials used for electronic components include

Aluminum

Lightweight, corrosion-resistant, and easily machinable, aluminum is often used for heat sinks, enclosures, and connectors.

Copper

Known for its excellent electrical conductivity, copper is commonly used for connectors, terminals, and electrical conductors.

Stainless Steel

Durable and resistant to corrosion, stainless steel is ideal for mechanical parts that need strength and reliability.

Plastics and Composites

Lightweight, corrosion-resistant, and easily machinable, aluminum is often used for heat sinks, enclosures, and connectors.

Material selection affects the part’s performance, heat dissipation, weight, and cost, so it’s important to choose materials that meet the specific needs of each component.

Machining Accuracy

Tight tolerances are essential in electronic parts, where even minor discrepancies can affect the overall performance of the device. Precision machining ensures that parts like sensors, lenses, and connectors are fabricated to exact specifications. SYM’s CNC machines provide micron-level precision, ensuring that every part aligns perfectly with other components in the system.

Surface Treatment

Surface treatments enhance the properties of machined parts, such as improving corrosion resistance, wear resistance, and aesthetic appearance. Common surface treatments for electronic parts include

Anodizing

Used for aluminum components, anodizing improves corrosion resistance and provides a protective oxide layer.

Plating

Electroless nickel plating, gold plating, and other coatings can improve conductivity and durability in connectors and electrical contacts.

Polishing

Used for lenses and mirrors, polishing ensures smooth, reflective surfaces necessary for optical clarity.

Precision Machining in Key Electronic Applications

Precision machining plays an essential role in the production of a wide variety of electronic devices. Some of the most common applications include:

Mobile Phone Manufacturing

The manufacturing of smartphones requires precision parts like buttons, connectors, camera lenses, and heat sinks. Machining these components to tight tolerances is critical for ensuring the phone’s overall performance, durability, and appearance.

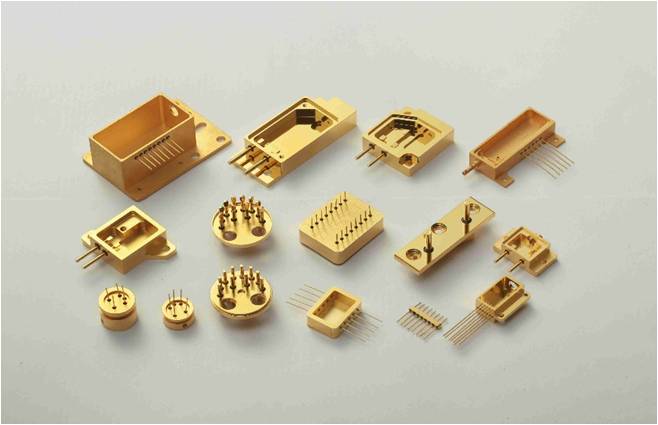

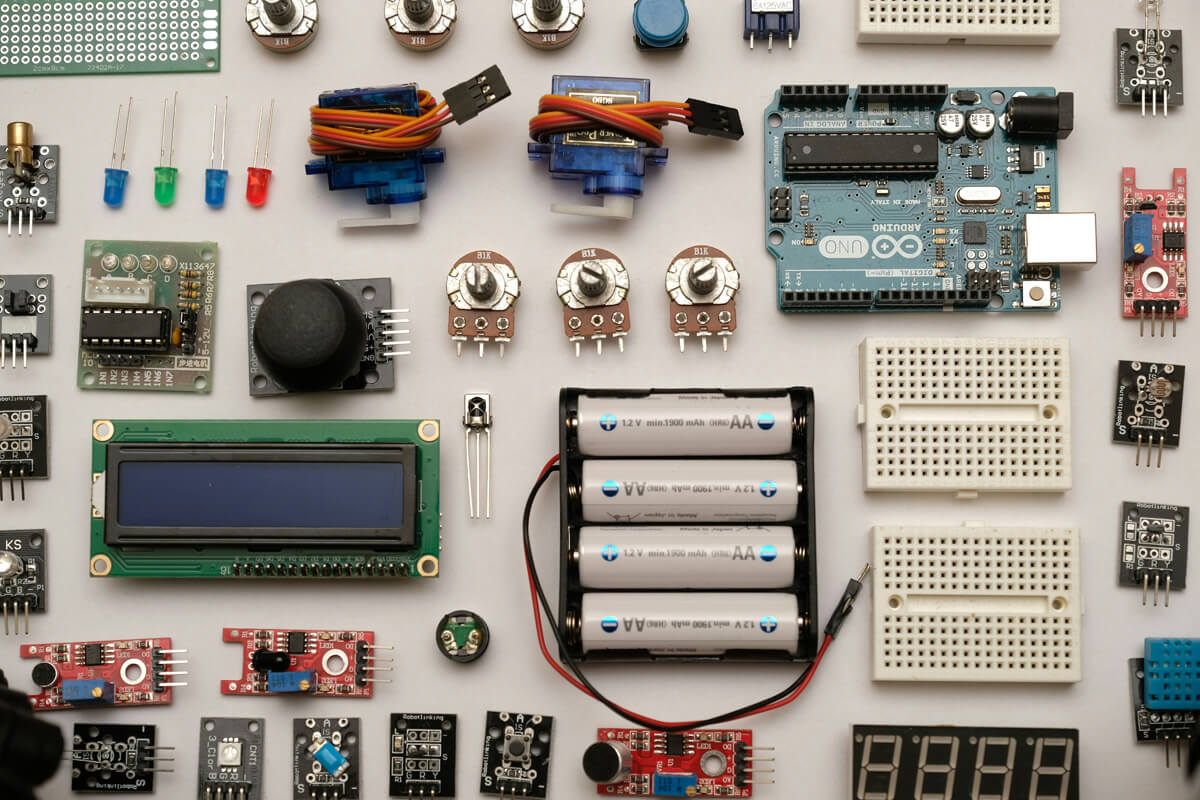

Electronic Components

Components such as resistors, capacitors, inductors, and semiconductors rely on precision machining to ensure they perform reliably under varying conditions, especially in devices like computers, cameras, and medical equipment.

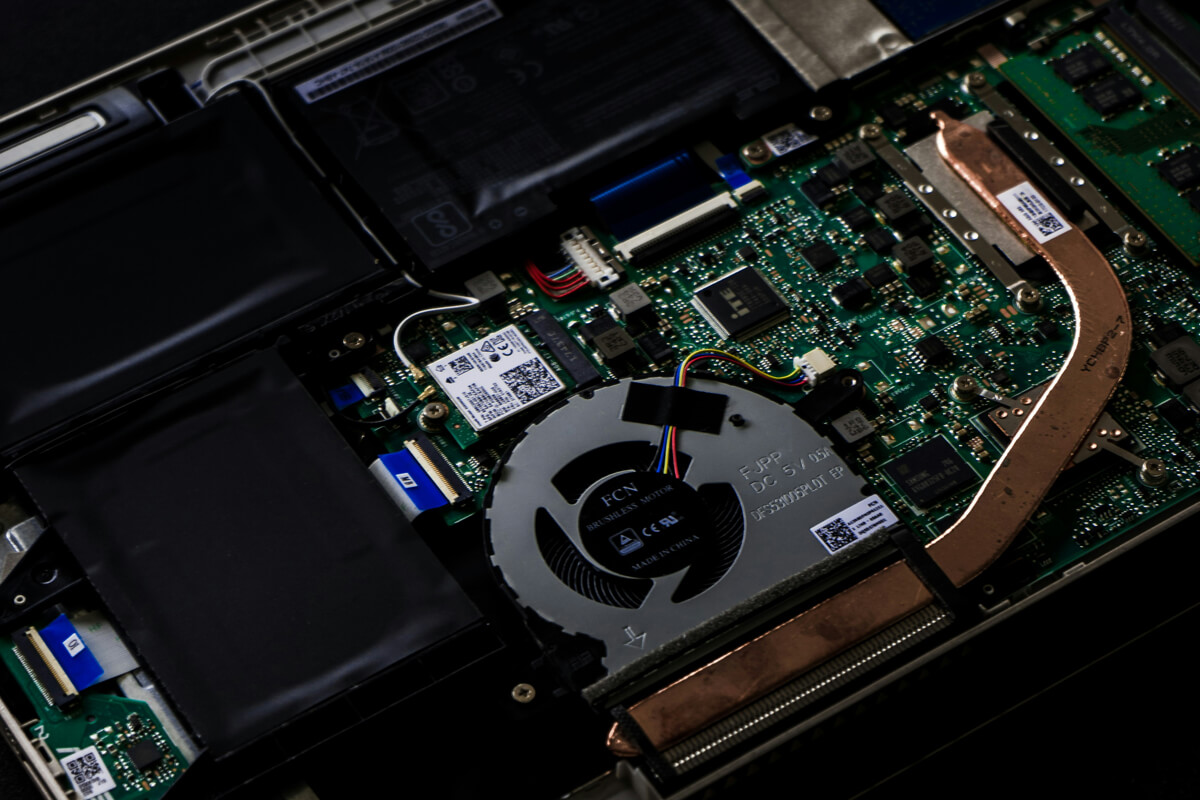

Computer Hardware

Precision machining is used to manufacture parts for motherboards, connectors, heat sinks, and cases. These components must fit precisely to allow for efficient assembly and optimal performance in high-powered devices.

Digital Cameras

Lenses, sensors, and motors in digital cameras require precision machining to ensure sharp focus, accurate color capture, and smooth operation. The high-quality machining of these components is essential to the overall quality of the final image.

Drones

Drones require various precision parts, including motors, propellers, connectors, and mounts. These parts must be lightweight, durable, and manufactured to strict tolerances to ensure stability and safe operation.

Smart Wearable Devices

Devices like smartwatches and fitness trackers contain tiny yet highly intricate parts, including buttons, sensors, connectors, and battery housings. Precision machining ensures these parts are small, light, and reliable enough to handle daily wear and tear while providing accurate readings.

Key Parts in Electronic Products That Require Precision Machining

In modern electronics, several key components rely on precision machining to ensure accuracy, performance, and reliability:

Lenses

Used in cameras, smartphones, and optical devices.

Sensors

Found in everything from mobile phones to industrial equipment, sensors require precise manufacturing to detect light, motion, or temperature.

Motors

Precision motors drive various devices, from drones to hard drives, and must be manufactured to tight tolerances.

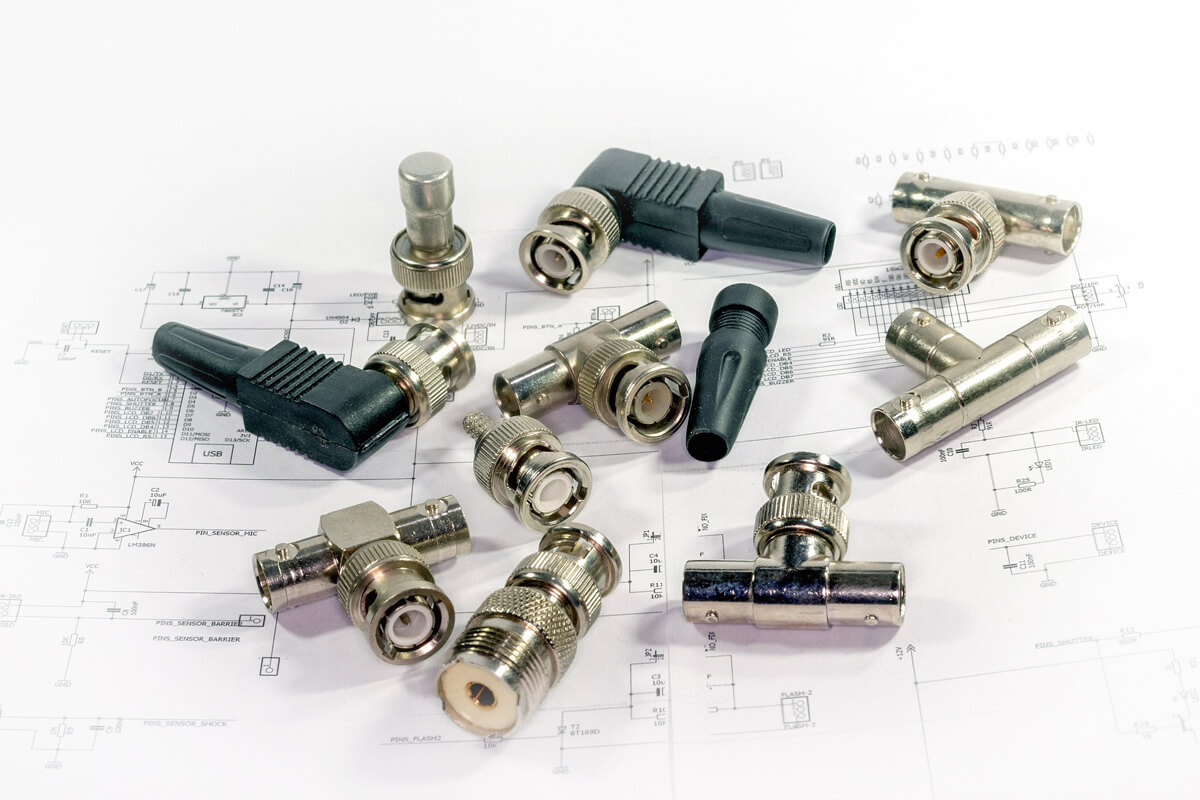

Connectors

Essential for ensuring seamless electrical connections, connectors must fit precisely to avoid signal loss or connectivity issues.

Electrical Terminals and Brush Parts

Used in a range of applications, these parts require precise machining to ensure reliable electrical conduction.

Elastic Parts

Components like gaskets or seals often require precision machining to maintain flexibility and ensure proper fit.

As electronic devices become more advanced and complex, the need for precision machining continues to grow. SYM Precision Machining, with its highly specialized manufacturing technology, experienced engineering team, and precision measuring equipment, is a trusted partner for producing high-quality electronic parts. Whether for mobile phones, computers, drones, or smart devices, we provide the accuracy, reliability, and timely delivery needed for successful electronic product development. By focusing on material selection, machining accuracy, and surface treatment, SYM ensures that every component meets the demanding requirements of the modern electronics industry.

Get Your Parts Into Production Today!

Want to learn more about SYM precision machining services, please contact us now.