Optical industry | Custom fiber optic connectors

Home » Industries Served » Optical Industry

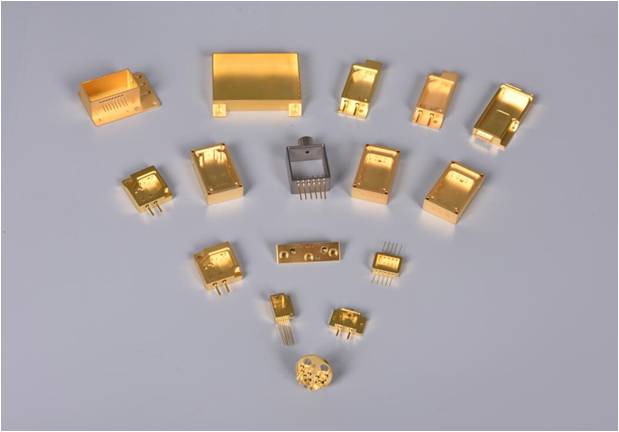

Hi quality cnc machining for custom fiber optic connectors in China.

SYM is a leader in Precision Machining Services and complete solutions for your custom fiber optic connectors, and some optical communication components, established in 1997. Our advanced precision machining technology can help you get qualified parts on time.

The normal material we used for optical mounts and housings

Aluminum alloy

Lightweight and easily machinable, aluminum is often used for optical mounts, housings, and frames. It can also be anodized for better corrosion resistance.

Stainless Steel

Provides strength and corrosion resistance for optical mounts in harsh environments.

Titanium

Used in applications requiring high strength-to-weight ratios and thermal stability, such as space optics.

At SYM, our entire machining shop is completely CNC turning, CNC milling, grinding, and EDM wire cutting with an enough capacity. With our customers on new applications from the custom design and prototype to the finished machined parts. We implement the latest technology and assure that every machined part meets customer guidelines.

In fiber optic connectors, the tolerance requirements for mounts and housings are critical to ensure proper alignment, reliable performance, and stability. Precise tolerances help maintain the optical path’s integrity by minimizing signal loss, reflection, and misalignment.

A general tolerance guideline for optical connector custom machining:

Achieving tight tolerances in fiber optic connectors is essential for signal integrity. These tolerances ensure proper alignment of the fibers, minimizing insertion loss, back reflection, and ensuring reliable connections, particularly in high-speed data transmission and critical communication applications.

- 1. Ferrule Tolerances

- Outer Diameter Tolerance: For ceramic ferrules, the outer diameter typically has a tolerance of ±0.001 mm (±1 micron). This precision is necessary to ensure a secure fit in the alignment sleeve.

- Concentricity: The concentricity between the ferrule’s outer diameter and the fiber core is generally within 1 to 3 microns. This tolerance is critical for minimizing insertion loss and ensuring fiber alignment.

- 2. Alignment Sleeve Tolerances

- Inner Diameter Tolerance: The alignment sleeve must match the ferrule's diameter closely. The inner diameter tolerance is usually within ±0.001 to ±0.002 mm. Ceramic alignment sleeves generally offer tighter tolerances than phosphor bronze sleeves, which is why they’re preferred in high-precision applications.

- 3. Connector Housing Tolerances

- Connector Body Dimensions: Tolerances for connector housings (made from plastics like PBT or metals like aluminum) are typically within ±0.05 mm. This allows the components to fit securely without excess play, ensuring that the ferrule remains stable when the connectors are mated.

- Flatness and Straightness: The surfaces and slots where ferrules and alignment sleeves fit require flatness and straightness tolerances within a few microns to maintain precise alignment of the fiber.

- 4. Mount Tolerances

- Panel Mount Openings: For fiber optic connector panel mounts (such as SC or LC duplex adapters), the tolerance of the mounting holes or cutouts is typically within ±0.1 mm. This allows the connector to fit snugly into the panel while allowing for easy assembly.

- Mating Surface Tolerances: The mating surfaces, which come into contact with corresponding connectors, usually have a tolerance within ±0.01 mm. This helps ensure a firm, stable connection and alignment for minimal signal loss.

Get Your Parts Into Production Today!

Want to learn more about SYM precision machining services, please contact us now.