Welding & Fabrication services

Home » Mechanical Assembly Services » Welding & Fabrication Services

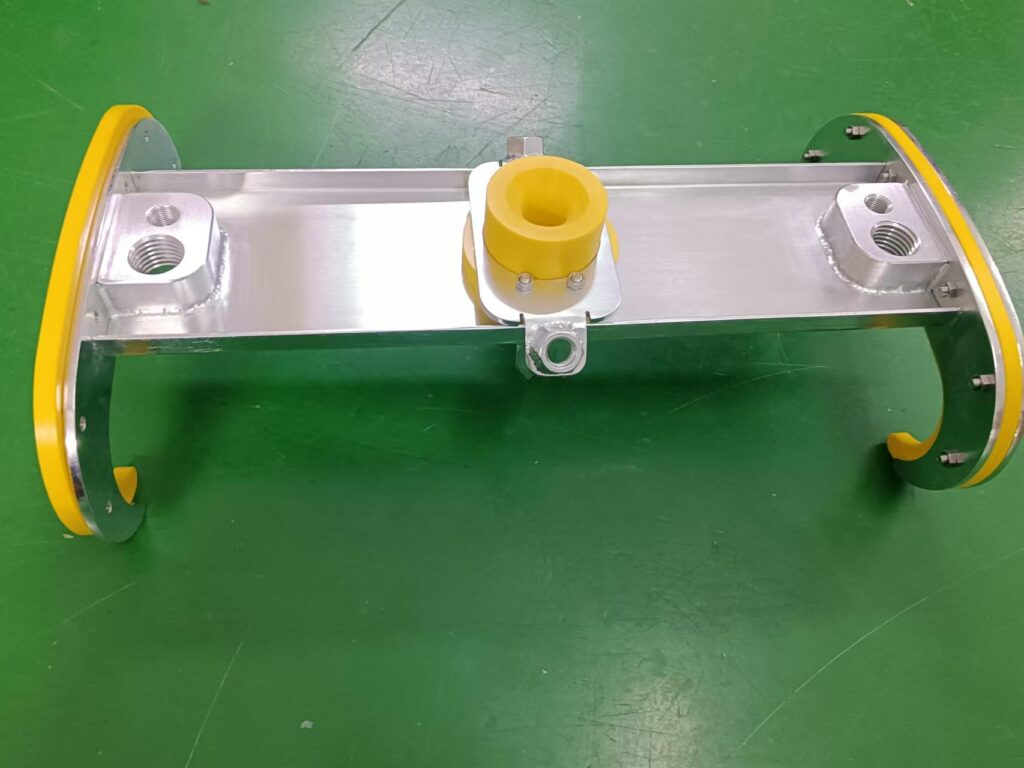

High quality welding & fabrication services in China

Trust our decades of industry experience to handle your most challenging welding and fabrication projects with precision and efficiency.

Key Aspects When Welding & Fabrication

Precision assembly through material fusion.

Welding & fabrication service is a specialized form of mechanical assembly work. It involves the precise joining of materials through welding techniques to create unified structures that meet specific functional requirements. Here are five key aspects of our welding and fabrication services:

Expert material fusion

Our skilled technicians use advanced welding techniques to seamlessly join various materials, ensuring structural integrity and durability.

Custom assembly solutions

We specialize in transforming individual components into cohesive, functional units tailored to your exact specifications and requirements.

Comprehensive project management

Comprehensive project management

Diverse application expertise

Our services cater to a wide range of industries, from automotive and aerospace to construction and manufacturing, adapting our techniques to meet industry-specific standards.

Quality assurance

We employ rigorous testing and inspection protocols to ensure that every welded assembly meets or exceeds the required functional and safety standards.

The material used in welding & fabrication project:

The material used in welding & fabrication project:

Steel (mild steel, stainless steel, carbon steel)

Aluminum and its alloys

Copper and copper alloys

Nickel and nickel alloys

Titanium

Surface finish options for welding and fabrication projects:

The purpose of surface finishing is to enhance the durability, corrosion resistance, and aesthetic appeal of the fabricated items.

Painting

Provides corrosion protection and aesthetic enhancement. You have a wide variety of color options available, tell us the RAL color number, we can do it.

Powder coating

Offers a durable and attractive finish. It also can get a wide range of colors available, with glossy or matte surface texture.

Galvanization

Protects against corrosion by applying a zinc coating. The common color of zinc coating is white, blue, black and yellow zinc coating.

Anodizing

Commonly used for aluminum to increase corrosion resistance and allow for dyeing.

Polishing

Improves appearance and can increase corrosion resistance, it’s widely used in some stainless steel welding & fabrication projects.

Sandblasting

Prepares surfaces for other treatments or provides a matte finish.

Get Your Parts Into Production Today!

Want to learn more about SYM precision machining services, please contact us now.