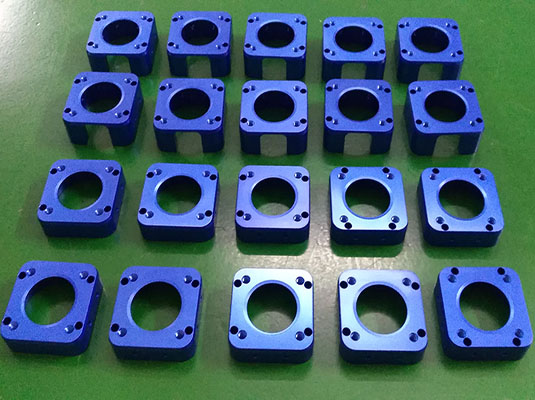

Work Gallery - Custom Machined Parts

Home » Work Gallery | Custom Machined Parts

Discover the best custom machined parts from China

For over 25 years, SYM Precision Machining has been a leading provider of precision machining services, delivering complete solutions for custom machined parts to customers worldwide. With thousands of successfully completed projects and a reputation for quality, SYM is dedicated to helping clients across various industries achieve success with highly customized and precisely manufactured components. Our commitment to quality, flexibility, and customer satisfaction makes us the trusted choice for businesses seeking reliable custom machining services from China.

What CNC Service We Can Offer

Aluminum machined parts

Stainless Steel Machined parts

Carbon steel machined parts

Tool steel machined parts

Titanium machined parts

Copper machined parts

Plastic machined parts

Here’s an in-depth look at SYM’s capabilities, including the materials we use, our advanced machining processes, surface finishes offered, and typical applications of our custom machined parts.

Materials Used for Precision Machined Parts

Aluminum Alloys (6061, 7075)

Known for their lightweight properties, high strength, and corrosion resistance, aluminum alloys are frequently used in automotive, aerospace, and consumer electronics applications.

Stainless Steel (304, 316, 17-4 PH)

Stainless steel is chosen for its excellent corrosion resistance, durability, and suitability for medical and food-grade applications.

Carbon Steel (1018, 1045)

Carbon steel is commonly used for parts requiring strength and wear resistance, such as structural and automotive components.

Brass and Copper

With high electrical conductivity and resistance to corrosion, brass and copper are ideal for electrical connectors, fittings, and plumbing components.

Titanium (Ti-6Al-4V)

Known for its strength-to-weight ratio and corrosion resistance, titanium is commonly used in aerospace, medical, and marine applications.

Plastics and Composites (PEEK, ABS, Polycarbonate)

Plastics are often chosen for lightweight parts, insulators, and non-conductive components, especially in electronics and medical devices.

Surface Finishes Offered by SYM

Surface finishing is crucial for enhancing the appearance, durability, and functionality of machined parts. SYM offers a variety of surface finishes to meet the specific requirements of each project

Anodizing

Applied primarily to aluminum parts, anodizing improves corrosion resistance, hardness, and can add a decorative color finish.

Plating

SYM provides various plating options, including nickel, zinc, and chrome plating, which improve wear resistance, corrosion protection, and electrical conductivity.

Powder Coating

Powder coating provides a tough, protective layer that is resistant to scratches, corrosion, and fading, commonly used for parts exposed to harsh environments.

Passivation

This process is used for stainless steel to enhance corrosion resistance and improve the metal’s longevity in harsh conditions.

Polishing and Sandblasting

To achieve a smooth or matte finish, SYM offers polishing for a reflective, smooth surface and sandblasting for a uniform, matte appearance.

Custom Finishes

SYM can provide custom surface treatments tailored to specific requirements, such as specialized coatings for heat resistance or enhanced conductivity.

Surface finishing is crucial for enhancing the appearance, durability, and functionality of machined parts. SYM offers a variety of surface finishes to meet the specific requirements of each project

Main Machining Processes at SYM

CNC Turning

CNC turning is ideal for producing cylindrical parts, such as shafts and bushings, with high precision and speed.

CNC Milling

CNC milling is a versatile process for creating complex geometries and detailed features, making it suitable for parts with flat, curved, or angled surfaces.

Grinding

Grinding is used to achieve extremely tight tolerances and a high surface finish, often required for components like gears and bearing parts.

Manual Milling and Turning

For lower-volume projects or specialized parts, manual milling and turning offer flexibility and a cost-effective solution.

EDM Wire Cutting

EDM (Electrical Discharge Machining) wire cutting allows for high-precision machining of hard materials and intricate shapes, commonly used for molds, dies, and other complex parts.

Welding

SYM offers welding services for joining metal components, useful in assemblies requiring durable, fused joints.

Sheet Metal Fabrication

With sheet metal fabrication, SYM can produce a variety of components, including enclosures, brackets, and housings, with precise bends and cuts.

Applications of Customized Machined Parts

SYM’s custom machined parts are used across various industries and applications, where precision, reliability, and quality are essential. Some of the primary applications include

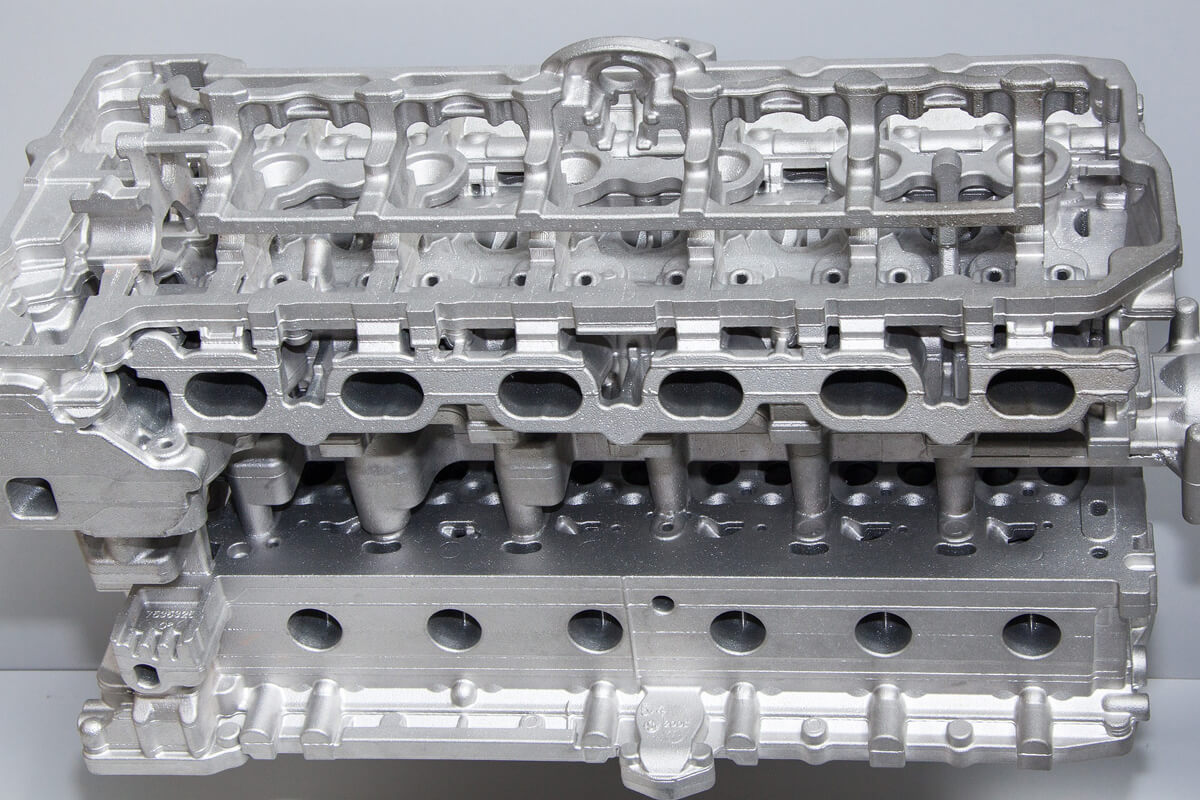

Automotive Components

SYM provides custom machined parts for engine components, transmission parts, and chassis components, helping automotive manufacturers achieve reliable performance.

Aerospace

We supply high-precision components for critical aerospace applications, including structural elements, engine parts, and landing gear components.

Medical Devices

SYM manufactures precision parts for surgical instruments, medical implants, and diagnostic equipment, where accuracy and biocompatibility are vital.

Consumer Electronics

SYM produces parts for mobile phones, laptops, and wearable devices, such as connectors, camera lenses, and housings.

Industrial Equipment

For heavy-duty equipment and machinery, SYM manufactures parts like gears, shafts, and fasteners that require strength and durability.

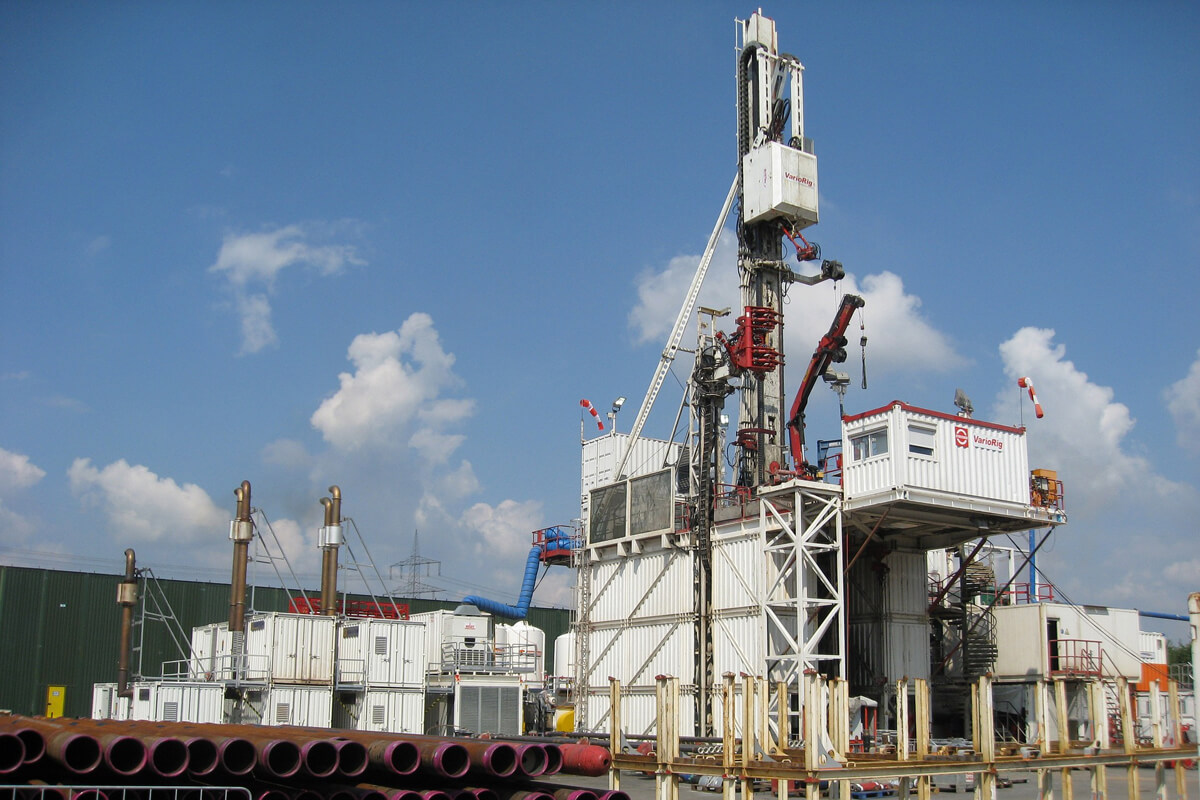

Oil and Gas

Plastics are often chosen for lightweight parts, insulators, and non-conductive components, especially in electronics and medical devices.

Robotics and Automation

We produce high-precision parts for robotic arms, actuators, and sensor mounts, supporting the growing field of automation and robotics.

The Benefits of SYM’s Custom Machining Services

SYM’s custom machining services provide several benefits to clients looking for high-quality, precision parts

High Quality and Precision

SYM’s advanced CNC technology, skilled engineers, and strict quality control ensure that each part meets exact specifications and tolerances.

No Minimum Order Requirement

SYM offers flexibility in order volume, allowing customers to order from as few as one unit to high-volume production runs.

Rapid Prototyping

For projects requiring fast development cycles, SYM provides rapid prototyping services, allowing clients to test and iterate designs quickly.

On-Time Delivery

With an experienced team and efficient production processes, SYM meets tight delivery schedules, ensuring that parts are ready when you need them.

Get Your Parts Into Production Today!

SYM Precision Machining stands as a leader in custom machining services, providing high-quality parts to a global customer base across diverse industries. With an extensive range of materials, surface finishes, and machining capabilities, SYM is equipped to deliver precision parts tailored to each client’s needs. From single prototypes to large-scale production, SYM’s commitment to quality, reliability, and customer satisfaction makes us a trusted partner for custom machined parts. Whether you need automotive components, medical device parts, or electronic connectors, SYM is here to bring your project to life with precision and efficiency.