At SYM Precision Machining, we understand that proper packaging is crucial for protecting your precision machined parts during transportation. To ensure that your products arrive at their destination in perfect condition, we follow a meticulous packaging process that accounts for the material, shape, and size of the parts. Below is our comprehensive guide to effective packaging for precision machined parts, with a focus on protecting the parts, reducing transit costs, and ensuring safety.

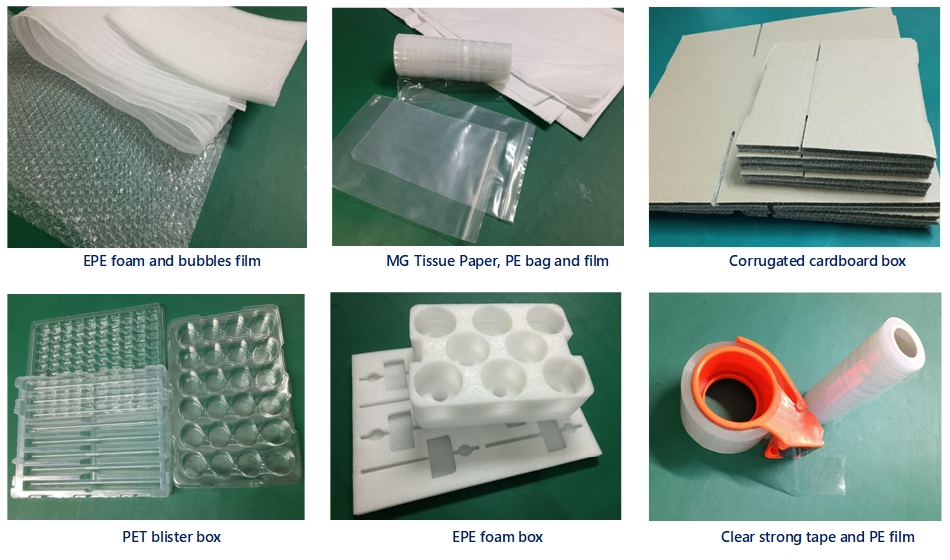

Select the Right Packaging Materials

The choice of packaging material is vital in protecting precision machined parts during shipping. We use environmentally friendly and clear materials to maintain visibility and prevent contamination. Our standard materials include: PE bag and film, MG Tissue Paper, EPE foam and bubbles film, cardboard box, PET blister box and Ply-wood crate, etc.

These materials ensure that parts are not only protected but also stay free from moisture, dirt, and other contaminants that could damage the surface quality.

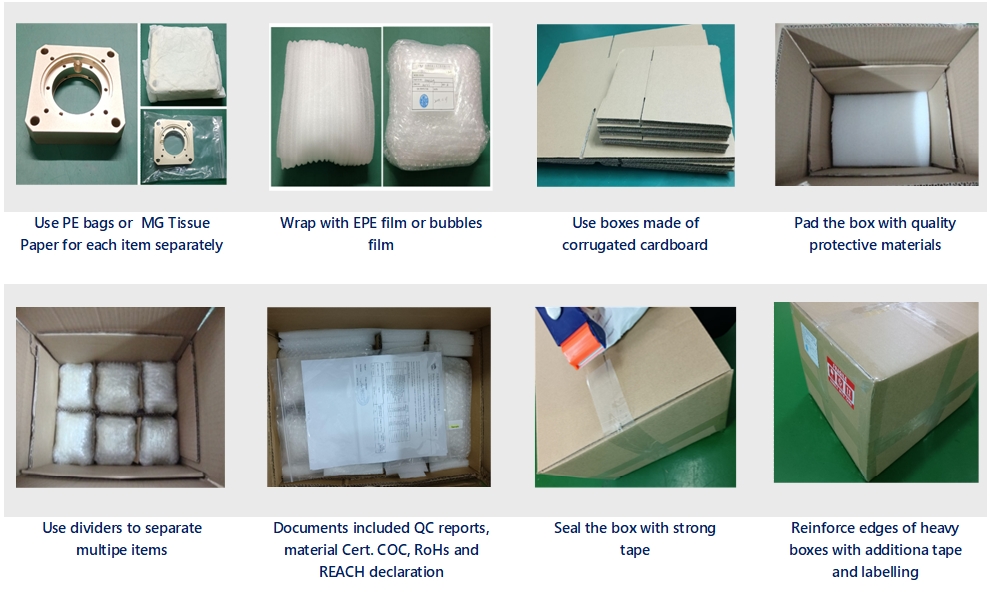

Find a correct packing method:

- Keep the Product Clean

- Wear Gloves: To avoid contamination from oil, dirt, or fingerprints, we always handle machined parts with clean gloves.

- Individual Protection: Wrap parts in PE bags or MG tissue paper to protect the surface from any external contamination. This layer serves as a shield against dust, dirt, and moisture.

- Avoid Direct Contact with Bubble Film: While bubble film is effective for cushioning, do not pack parts directly in bubble film. Doing so can leave bubble marks or impressions on the surface of the parts. Always use PE bags or MG tissue paper as a protective layer before using bubble film.

- Packing Method for Different Materials

- Carbon Steel Parts: Carbon steel is prone to rust and requires special attention to prevent corrosion.

- Dip in Anti-Rust Oil: To protect against rusting, dip carbon steel machined parts in anti-rust oil before packaging.

- Use PE Bags: After dipping in oil, wrap the parts securely in PE bags to protect them from moisture and environmental factors.

- Large Parts: Larger machined parts require more flexible packaging.

- Use PE Film: For large parts, PE film is an ideal choice as it can wrap around irregularly shaped components and provide a good level of protection during transit.

- Mixed Packaging: When shipping or packagingprecision machined parts of multiple materials.

- Aluminum parts and plastic parts should always be placed on top, steel machined parts placed at the bottom of the box.

- Light partplaced on top, heavy parts should always be placed at the bottom of the package to ensure stability and to prevent lighter parts from being crushed or deformed.

- Packing Method for Different Shapes of Products

- Small, Complex Parts: Mass-produced small and complex machined parts require more tailored packaging solutions.

- Blister Boxes or EPE Foam Boxes: Use blister boxes or EPE foam boxes for these types of parts. These packaging options provide extra protection and help keep parts secure, preventing any shifting during transport.

- Heavy or Bulky Parts: For heavy parts, the packaging needs to be robust to ensure safety during shipping.

- Plywood Crates: For machined parts that weigh more than 15kg, we use plywood crates. These crates offer maximum protection for heavy or fragile components and ensure safe handling during transportation.

- Mixed Packaging: When dealing with parts of different shapesor significant size differences. The main concern is preventing abrasion, scratching, deformation, or improper alignment when parts come into contact with each other.

- Sheet metal partsare typically thin, flat, and more vulnerable to bending or warping than solid, bulky metal parts. Placing them at the top of the package prevents heavier, more rigid parts from pressing down on them. Or create separate layers between sheet metal and other machined parts, using cardboard dividers or foam sheets to avoid direct contact between parts with differing shapes and sizes.

- When parts have large dimensional differences, particularly in height, width, or shape, they should not be placed together.Using separate boxes for different groups of parts.

By following these detailed packing methods, we ensure that SYM Precision Machining provides you with the highest level of protection for your machined parts. Each part is packed in a way that suits its material, shape, and weight, ensuring safe arrival at your destination without damage.

Safety and Transportation Considerations for Precision Machined Parts

At SYM Precision Machining, we consider several key transportation safety factors when packaging and shipping your products to ensure they arrive in perfect condition and comply with transport regulations.

- Weight Limitations for Packaging

- Cartons: To prevent overloading and ensure safe handling, we limit the weight of each carton to 15kg. This weight limit helps avoid the risk of damage during loading, unloading, and transport, ensuring that the parts are handled with care and reducing the risk of breakage.

- Pallets/Plywood Boxes: For larger or heavier shipments, the weight limit per pallet or plywood box is typically set at 200kg. This ensures that the packaging can withstand the weight during transit, providing both protection for the parts and compliance with transport regulations.

- Full Filling of Empty Spaces

- Prevention of Shifting: To prevent the machined parts from shifting or being damaged during transportation, it is essential to fill any empty space inside the packaging. By using protective materials like foam, air cushions, or other fillers, we ensure that the parts stay securely in place, minimizing the risk of damage due to movement during transit.

- Maximizing Protection: Properly filling the empty space also prevents parts from colliding with one another, which could lead to scratches, dents, or other forms of damage. This is particularly important for smaller or more delicate components.

- Consideration of Package Volume to Save Transit Costs

- Optimizing Package Size: It’s not just about protecting your parts—it’s also about optimizing the volume of the package to help reduce transit costs. When packing, we carefully consider the size and shape of each item to avoid excessive unused space that would otherwise increase shipping fees. By packing products efficiently, we can help reduce your shipping costs without compromising the safety or integrity of the parts.

- Space Optimization: In cases where multiple parts are being shipped, we strive to group them together in a way that makes the most efficient use of available space, while ensuring product safety,thus reducing the overall volume of the package and keeping shipping costs as low as possible.

Documentation for Precision Machined Parts Shipping

At SYM Precision Machining, we recognize that proper documentation is key to building trust and ensuring customer satisfaction. With every shipment, we ensure that all necessary certifications and reports are included, giving you the confidence that your precision machined parts meet the highest standards of quality and compliance.

- Raw Material Certifications

- What It Is: Raw material certifications verify the quality, origin, and compliance of the materials used in the production of machined parts.

- Why It’s Important: These certificates ensure that the raw materials meet industry standards and specifications. By including raw material certifications, we provide proof of material quality and traceability, which is particularly important in industries such as aerospace, medical, and automotive.

- QC Inspection Reports

- What It Is: Quality Control (QC) inspection reports detail the results of various tests and checks conducted on the parts to ensure they meet the specified dimensions, tolerances, and overall quality standards.

- Why It’s Important: These reports provide our customers with documentation confirming that the parts were thoroughly inspected before shipment. They offer peace of mind that all parts comply with the required quality standards and are free from defects. Inspection reports may include:

- Dimensional checks

- Surface finish measurements

- Functional testing (if applicable)

- Visual inspections

- Certificate of Conformance

- What It Is: The Certificate of Conformance (CoC) is a document that certifies that the parts shipped are in compliance with the agreed specifications and standards.

- Why It’s Important: This certificate provides an official confirmation that the parts meet the contractual and regulatory requirements. It is often required for customers in highly regulated industries like aerospace, medical devices, and defense.

- RoHS and REACH Declarations

- What It Is:

- RoHS Declaration: RoHS (Restriction of Hazardous Substances) is a regulation that restricts the use of certain hazardous materials in electrical and electronic equipment. The RoHS declaration certifies that the parts are free from restricted substances such as lead, mercury, cadmium, and other toxic chemicals.

- REACH Declaration: REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is an EU regulation aimed at improving the protection of human health and the environment from the risks of chemicals. The REACH declaration ensures that the materials used in manufacturing parts comply with this regulation.

- Why It’s Important: For customers in the electronics, automotive, and other regulated industries, the RoHS and REACH declarations are critical for ensuring compliance with environmental standards and avoiding penalties.

- Additional Documentation (As Required)

- Custom-Specific Documentation: Depending on the specific requirements of the customer or industry, we may include additional documents such as:

- Material Certificates

- Plating and Coating Specifications

- Test Reports

- Calibration Certificates

If you have specific documentation requirements or need additional certifications, feel free to reach out to our team to discuss your needs. We’re here to provide you with a complete solution for all your machining needs.!

Package Labeling for Precision Machined Parts

Proper labeling is a critical step in the packaging process, as it ensures clear identification, safety, and traceability of the precision machined parts during transit. At SYM Precision Machining, we take great care in ensuring that all of our shipments are clearly labeled, providing both necessary product information and any safety-related warnings. Here are the key types of labels included with our packages:

- Package Label

- What It Is: The package label contains essential information about the contents of the package, such as:

- Order Number: To help identify the specific customer order.

- Product Specifications: To describe the machined parts, such as the Part Name, Drawing Number, Revision Number.

- Quantity: The number of items in the package to ensure correct inventory and shipment tracking.

- Production Date: The date when the parts were manufactured, which helps in traceability and quality control.

- Inspector: To show who inspect the machined parts, this helps with tracking and improvement.

- Customer Name and Supplier Name: Clear identification of the recipient to avoid shipping errors.

- Why It’s Important: The package label ensures that both the sender and recipient have a clear understanding of what is inside the package. This makes it easier to manage shipments and inventory, reduces the risk of mistakes, and ensures that all parts are shipped to the correct destination.

- Warning Label

- What It Is: A warning label is used to highlight any important safety or handling information related to the contents of the package. Examples of warning labels include:

- Fragile: Indicates that the contents are delicate and should be handled with care.

- Heavy: Warns that the package contains heavy components and may require special handling.

- Temperature Sensitive: Alerts that the contents could be affected by temperature extremes (e.g., for certain plastics or sensitive materials).

- Do Not Stand Upside Down:This label ensures that the package is handled correctly, preventing mishaps such as parts shifting or being damaged if the package is placed incorrectly. Especially for some mixed package with light parts on top and heavy parts at the bottom.

- Keep Dry: Indicates that the parts inside are susceptible to moisture damage (especially important for materials like carbon steel or electronic components).

- Why It’s Important: Warning labels help inform handlers and shipping personnel about specific care requirements for the package. This reduces the risk of damage during transportation and ensures that the package is handled according to its specific needs.

- Other Important Information

- Barcodes: A barcode or QR code is sometimes included for easy scanning and tracking during the shipping and receiving process. This makes it quicker to verify inventory, manage orders, and streamline logistics.

- Compliance and Certification Labels: In some cases, there may be additional compliance labels indicating that the parts conform to regulatory requirements (e.g., RoHS, REACH) or certification standards (e.g., ISO 9001, AS9100D). These labels confirm that the parts have met necessary industry and regulatory standards.

Proper package labeling is an essential part of our shipping process at SYM Precision Machining. Our clear, informative, and accurate labeling system ensures that your precision machined parts are handled correctly and arrive at their destination safely and efficiently. Whether it’s a product label for easy identification or a warning label for special handling requirements, we make sure every package is labeled correctly to meet your needs.

If you have specific labeling requests or would like to customize your package labels, please don’t hesitate to let us know. We’re here to ensure your shipping experience is smooth and hassle-free!

An example packaging guidance of machined parts at SYM precision machining

SYM Shipping & Packaging Guidance: Ensuring Safe Delivery of Your Precision Parts

At SYM Precision Machining, we understand that high-quality packaging and reliable shipping are essential to ensuring that your machined parts arrive safely, on time, and in perfect condition. Our experienced Packaging Department and comprehensive Shipping Guidelines are designed to protect your parts throughout transit, no matter where they are being shipped worldwide.

Our Packaging Team

- Experienced Packaging Team: Our 5 dedicated packing staffeach have over 10 years of experience in packaging hardware and precision parts. Their expertise ensures that every item is packed securely, using the most appropriate methods for different types of parts.

- Eco-Friendly Packaging Materials:

We prioritize sustainability and use eco-friendly materials to package parts, including:

- Kraft paper

- PE film

- PE bags

- Bubble wrap

- Pearl cotton

- Blister boxes

- Corrugated cartons

- Plywood boxes

These materials are carefully selected to offer the best protection while minimizing environmental impact.

- Custom Packaging Solutions:

Based on the structure, size, and material of each product, we design a tailored packaging solution to ensure maximum protection during transit. We consider the fragility, weight, and shape of the part, as well as any special handling instructions, to choose the most suitable packaging.

Why Choose SYM for Your Shipping and Packaging Needs?

- Experienced Team: With over 10 years of expertise, our team ensures that every part is carefully packed to meet the highest standards.

- Safe Delivery: We take every precaution to ensure your parts arrive undamaged and on time, regardless of the shipping destination.

- Tailored Solutions: Customized packaging for different types of parts, from small components to larger, more delicate items.

- Eco-Friendly Approach: We use environmentally friendly materials to reduce the environmental footprint of our packaging.

Your Trusted Partner for Shipping & Packaging

At SYM Precision Machining, we go the extra mile to ensure that your products are securely packaged and delivered without any issues. With our experienced team, eco-friendly materials, and reliable shipping process, you can trust SYM to handle the logistics of your precision parts with care and efficiency.

Contact us today for more information on how we can meet your packaging and shipping needs!