keep cost-effective design to reduce costs and save money on precision machining.

1.Material select Select raw material with good machining performance,such as AL6061,Mild steel. On the premise of ensuring the performance of the product,avoid expensive materials. Size of material,try to use the material thickness (diameter) available on the market,especially for tube,if can find suitable size of tube for your product without machining inner surface,that would save more money.

Select raw material with good machining performance,such as AL6061,Mild steel. On the premise of ensuring the performance of the product,avoid expensive materials. Size of material,try to use the material thickness (diameter) available on the market,especially for tube,if can find suitable size of tube for your product without machining inner surface,that would save more money.

2.Order Quantities Order large quantities of same part to reduce unit price.For a small number of orders, if need to use CNC machine, the cost will go up more.Because each kind of product be done by CNC precision machining including programming,fixture making, machine commissioning, these labor costs be calculated in the unit price of the product.

Order large quantities of same part to reduce unit price.For a small number of orders, if need to use CNC machine, the cost will go up more.Because each kind of product be done by CNC precision machining including programming,fixture making, machine commissioning, these labor costs be calculated in the unit price of the product.

Keep simple shape,the simpler the geometry of the parts surface,the better the machining process.Split up complex parts,especially for parts with deep pockets or multiple faces,may design and machining as separate simple parts,then weld or bolt together.

4.Internal corner

Use an in side corner radius 0.03″ Min for tool diameter.

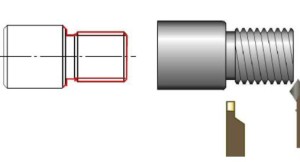

5.Relief groove

Gear,thread, keyway processing must have a relief groove,otherwise the tool will be damaged. Keyway, pin hole is arranged in the same direction,the height of the orifice should be the same plane,for one installation.

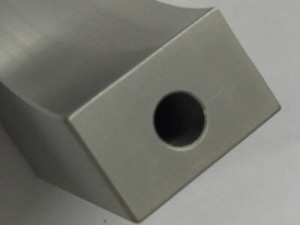

6.Hole depth

If can use thru hole,don’t use blind holes. Avoid deep holes (depth is 10 times larger than diameter.

7.Tolerance management

Limit tight tolerance,the lower the average manufacturing accuracy of the precision machining parts, the better the structure of the product.According to the function of product requirement,assign tight tolerance to critical features,keep all other feature as standard tolerance +/- 0.005″.

8.Surface roughness  When it comes to surface roughness specifications,use N6~N7 is easy to reach by turning or milling, up to N5,the surface would be done by grinding or polish,the cost would be increased 30%~40%。

When it comes to surface roughness specifications,use N6~N7 is easy to reach by turning or milling, up to N5,the surface would be done by grinding or polish,the cost would be increased 30%~40%。