Precision CNC Machining Services in China

Home » CNC Machining Services

Find the reliable cnc machining service for your precision machined parts, which produce and deliver on-demand.

Are you troubled by the following questions when you choosing a reliable cnc machining supplier?

- 1. Delayed delivery, orders are not followed up in time.

- 2. Product quality is unstable, poor appearance.

- 3. Production strength is not enough to achieve the expected results

- 4. Low service efficiency, slow response

SYM machining is a leading precision CNC machining services supplier in China, we can solve all above issues for you, and support you win more projects.

What CNC Machining Service We Can Offer

5 Axis CNC Machining Services

Prototype CNC Machining Services

CNC Milling Services

CNC Turning Services

Production Ability

With over 100 sets of CNC machines, including CNC milling and CNC turning, We offer a wide range of machining capabilities and can work with you to develop custom solutions that meet your specific requirements. Whether you need small or large quantities of machined parts, we have the capacity to deliver on time and with the highest quality.

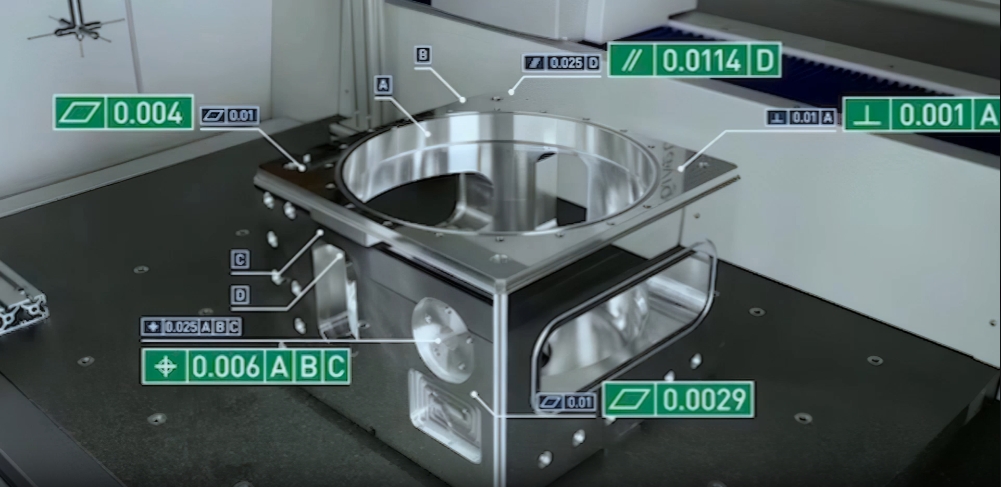

Equipment advantage

At SYM machining, we have a number of advanced automated production equipment, accurate measuring instruments. Our team of experts uses the latest technology and techniques to ensure that our products meet the highest standards of quality and precision.

Quality assurance

No worries after sale

We provide perfect after-sales service, there is a sales service team at SYM machining, they follow up and deal with any problems you encounter, and reply you within 24 hours. We always provide you professional and perfect solutions of your precision CNC machining needs.

What is precision cnc machining?

Precision cnc machining is a process of processing parts to very high tolerances with a machine tool and computer numerical control (CNC). The products produced by this process are called precision cnc machined parts. According to the shape and structure of cnc machined parts, it can be divided into cnc milling, cnc turning, cnc turning and milling composite processing, and 5-axis cnc machining. Its high-speed cutting tools can cut almost any metal alloy and plastic with high precision, making custom machined parts suitable for nearly every industry.

Materials Used for CNC Machining

Aluminum alloy

AL6061-T6, AL7075-T6, AL6082, AL5083, AL5052, AL2024, AL6060, etc.

Stainless steel

SS304, SS303, SS316, SS304L, SS316L, SS440C, SS420 SS416, SS17-4 PH, etc.

Carbon steel

C1018, C1020, C1045, 16CrMn5, 42CrMo4, AISI 1117, St52, etc.

Tool steel

O1 tool steel , A2 tool steel, D2 tool steel, S7 tool steel, etc.

Titanium

Ti-6Al-4V (grade 5), Ti-6AI-2Sn-4Mo-2Zr-1Fe (grade 18), Ti-6AI-4Sn-4Mo-2Zr-0.08Si (grade 11), Titan grade 2, etc.

Copper alloy

Brass (C26000, C27000), Copper (C11000, C10100, C12000), Bronze (C51900, C52100), etc.

Plastic

POM (Delrin, Acetal), Teflon (PTFE), PE (UPE), ABS, PVC, Nylon (PA), PEEK, PVDF, PC, etc.

SYM precision CNC machining ability

- Precision CNC Turning

Machining size range: OD500 x L1000mm (MAX), OD20”x L40” (MAX).

Accuracy: 0.01mm (0.0004”).

- Precision CNC Milling

Machining size range: L 950 x W 850 x H 650mm (MAX), L 37” x W 33” x H 26” (MAX).

Accuracy: 0.02mm (0.0008”)

Precision cnc machining tolerance

In design and manufacturing, tolerance is the acceptable range of variation of the dimensions of a machined part. We generally machining the cnc machined parts according to your 2D drawing, keep the tolerance which indicated on the drawing. If there is only 3D drawing, unless otherwise specified, SYM’s standard tolerance is applied to ISO 2768-f for metal machined parts and ISO 2768-m for plastic machined parts. The tight tolerance we can handle by CNC machining is 0.01mm (0.0004”), if tighter tolerance required, let’s look toward the precision grinding services, precision grinding services, or wire EDM machining services.

| General Tolerances ISO 2768-1 standards | ||||

| Basic size ranges (mm) | Tolerance Class Description for Linear Dimensions | |||

| f (fine) | m (medium) | c (coarse) | v (very coarse) | |

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | — |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4 |

| Radi and Chamfer | Tolerance Class Description for Radii and Chamfer Heights | |||

| 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

| Angle Short Side Length | Tolerance Class Description for Angular Dimensions | |||

| up to 10 | ±1° | ±1° | ±1°30′ | ±3° |

| over 10 up to 50 | ±0°30′ | ±0°30′ | ±1° | ±2° |

| over 50 up to 120 | ±0°20′ | ±0°20′ | ±0°30′ | ±1° |

| over 120 up to 400 | ±0°10′ | ±0°10′ | ±0°20′ | ±0°30′ |

| over 400 | ±0°5′ | ±0°5′ | ±0°10′ | ±0°20′ |

Our Lastest Precision CNC Machined Parts

Cnc milling parts, cnc turning parts, 4 axis cnc machining parts, 5 axis cnc machining parts, Swiss machining parts

Precision CNC machining FAQs

Q1. We only have 3D drawing, can you complete the cnc machined part without PDF drawing?

A: Yes, please advise the material and the tolerance of key dimensions, SYM machining team will combine your special notes and 3D mold to complete the cnc machined part.

Q2. What kind of precision cnc machining services do you offer?

A: At SYM, we can provide you precision CNC milling services, precision CNC tuning services, prototype CNC machining services, 4 axis cnc machining services, 5 axis cnc machining services and cnc turn-mill combination machining services.

Q3. What about the order quantity? Is there MOQ require for the cnc machining parts?

A: There is NO MOQ at SYM, we can accept the quantity of cnc machining orders from 1 piece to 10000 pieces. The cnc machining cost based on the order quantity, the price would be higher for small quantity requirement.

Q4. What kind of the surface finish of machined parts does cnc machining leave?

A: It depends on the shape of the machined parts, for turned parts, we can get very nice surface with roughness Ra0.8 um (32uin) by CNC turning. For milled parts, we could see slight visible tool marks on the machined parts which is completed by cnc milling, the surface roughness is Ra1.6~3.2um (63~125 uin).

Q5. How long can we expect to receive the machined parts after placing the order?

A: The lead time is based on your order quantity, our general delivery time is 7~ 15 days, add another 4~6 days for shipment by air, (UPS, Fedex or DHL). For some mass production, we can talk case by case, and we also can choose the shipment by ocean.

Q6. We worry about the quality issues when we paid 100% payment for machined parts

A:The cnc machined parts we provide are of guaranteed quality, if there is any quality issue, we will provide the replacements free of charge or refund the payment.