4 Tips for tolerance design of machine parts

When designing a machine parts, the step of adding tolerance requirements to the part is called tolerance design. Four tips as below for your reference.

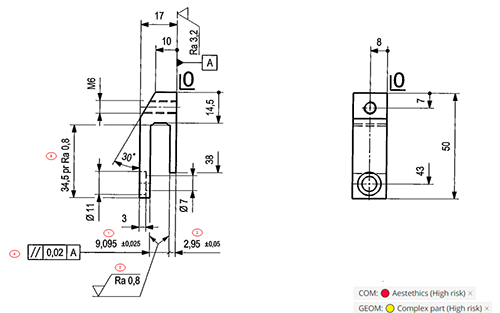

1. Tolerances are critical to part design, but not all parts or features of parts need to be toleranced. In order to save processing time and cost, only the key features of the machine parts need to be toleranced, such as the matching dismensions of the parts.

2. Avoid tight tolerance. Strict tolerance requirements often require more precise control, additional measuring tools or fixtures, and longer lead times. All of this action would be spent more processing costs.

3. When designing tolerances, don’t forget to check the machining capabilities and the accuracy of production equipments. But if you order machine parts from SYM, you don’t have to care about details such as the processing capacity. Our various types of production equipment can find the most suitable processing solution for your machining needs. And guarantee to meet the tolerance requirements of customers.

4. Keep in mind the properties of the raw material. The difficulty of machining a part to a specific tolerance depends largely on the raw material. Soft materials are more difficult to maintain specific tolerances,because the material may bend during machining.