One-stop Machining Services Manufacturer in China

Cost-effective CNC machining, prototyping, and production of custom parts. Your project is unique, and we deliver the service it demands.

- Competitive Price 30% cost save

- Fast turnaround in 7 days

- Tolerances down to ±0.005mm

- Global Delivery

- Real Factory welcome visit

Our Machining Services

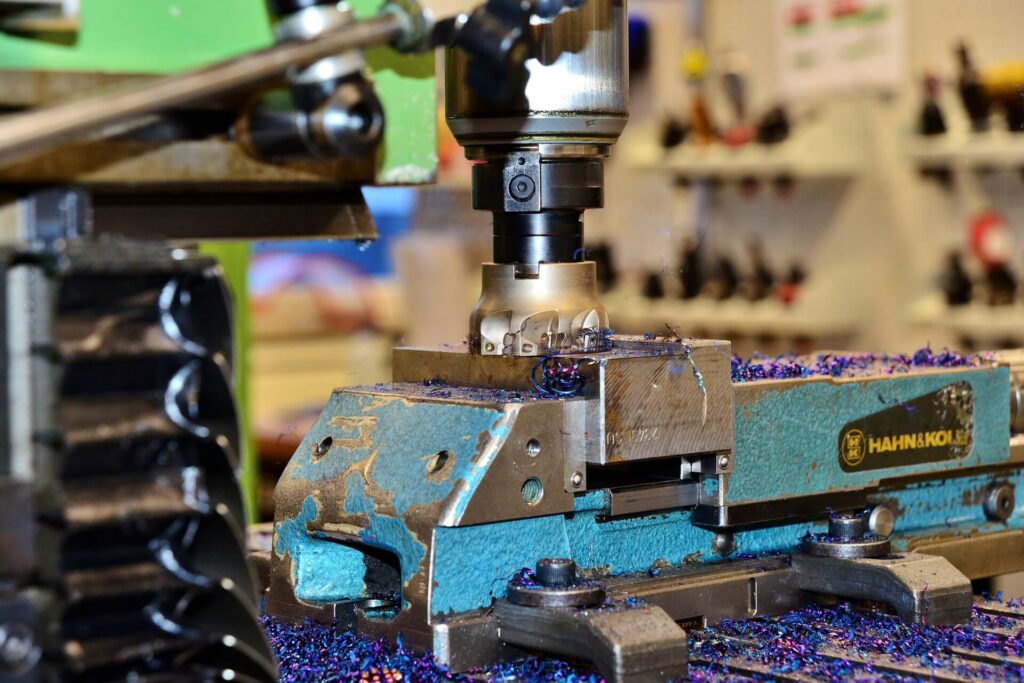

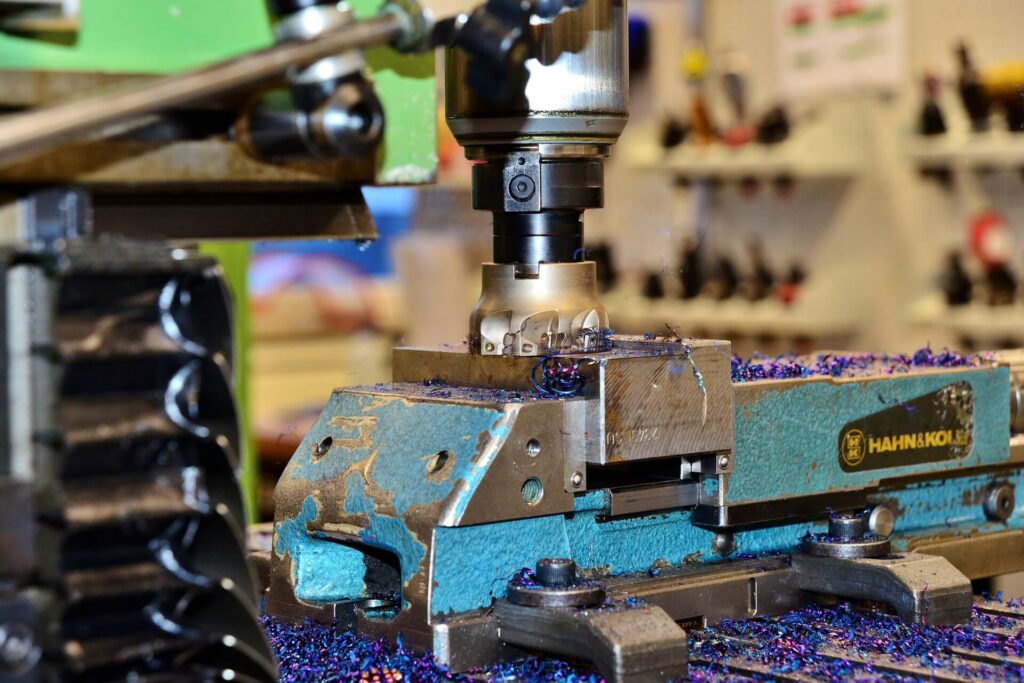

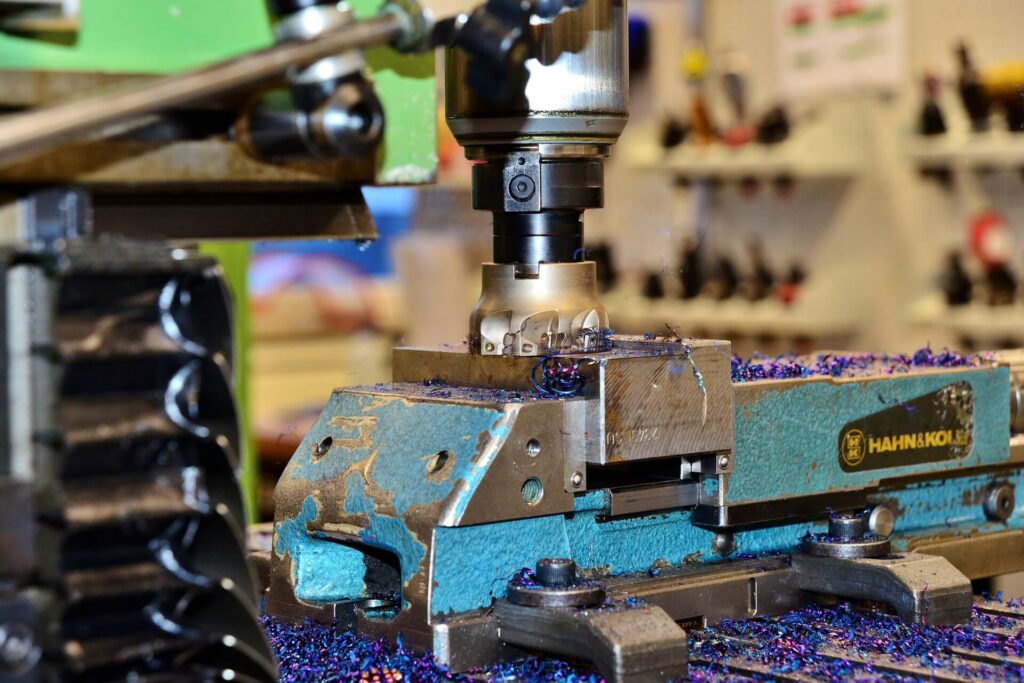

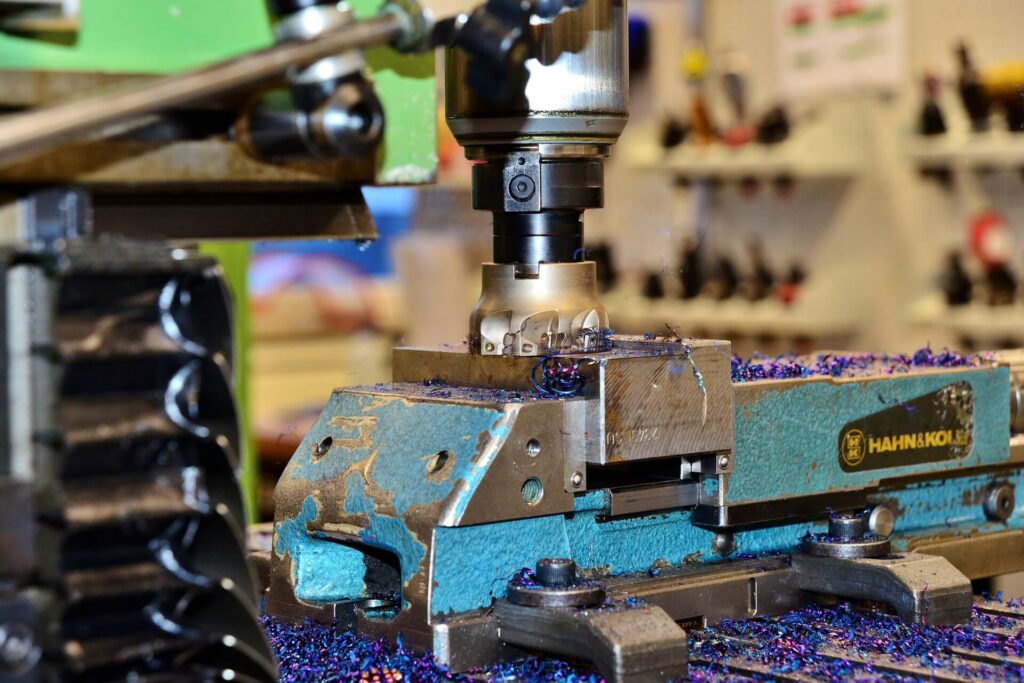

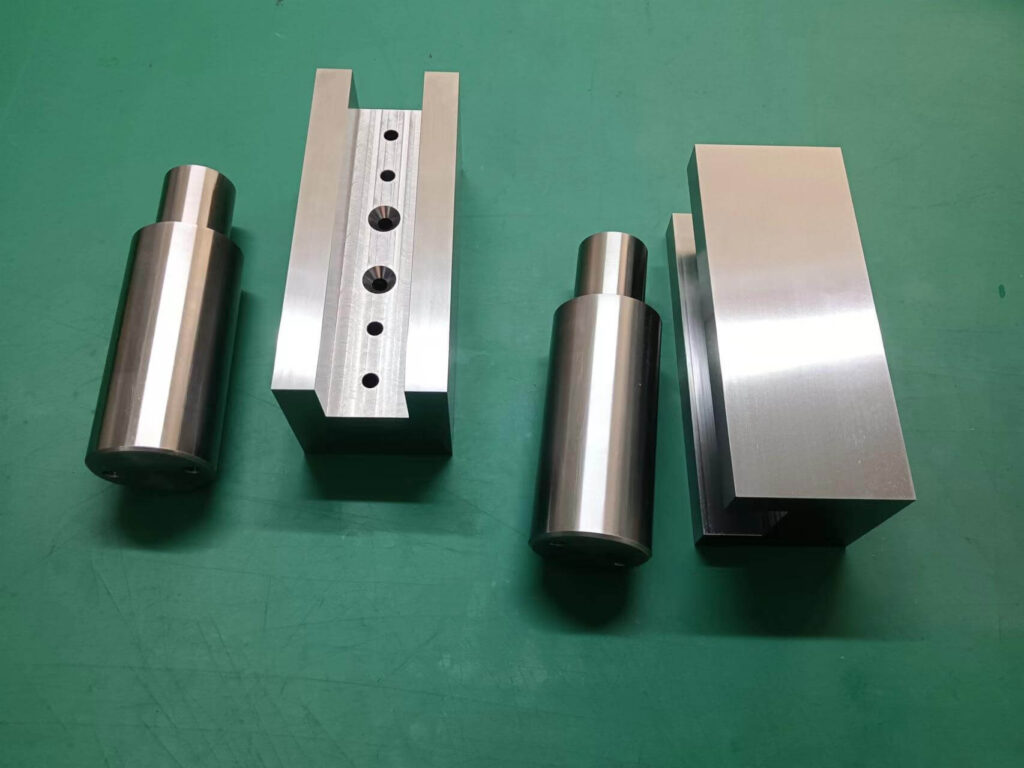

CNC Machining

It can be divided into cnc milling, cnc turning, cnc turning and milling composite processing, and 5-axis cnc machining.

Precision Grinding

Surface grinder, center-less grinder, cylindrical ID/OD grinder, and manual surface grinder.

Wire EDM Machining

Mechanical Assembly

Custom fixtures, welding and fabrication, press-fit assembly works, and mechanical fastening.

Surface Finish

wide range of metal surface finishing: electroplating, black oxide, Painting, powder coating, anodizing, polishing, Sandblasting, etc.

Advanced On-Demand Manufacturing Solutions

CNC Machining

CNC Lathe, CNC Turning, 3 Axis CNC Milling, 5 Axis CNC Machining Service for simple and complex geometrical parts.

CNC Machining

CNC Machining

CNC Machining

Various Material Availble for you

Select the ideal materials for your customized parts by understanding their characteristics.

Aluminum

Known for their lightweight properties, high strength, and corrosion resistance, aluminum alloys are frequently used in automotive, aerospace, and consumer electronics applications.

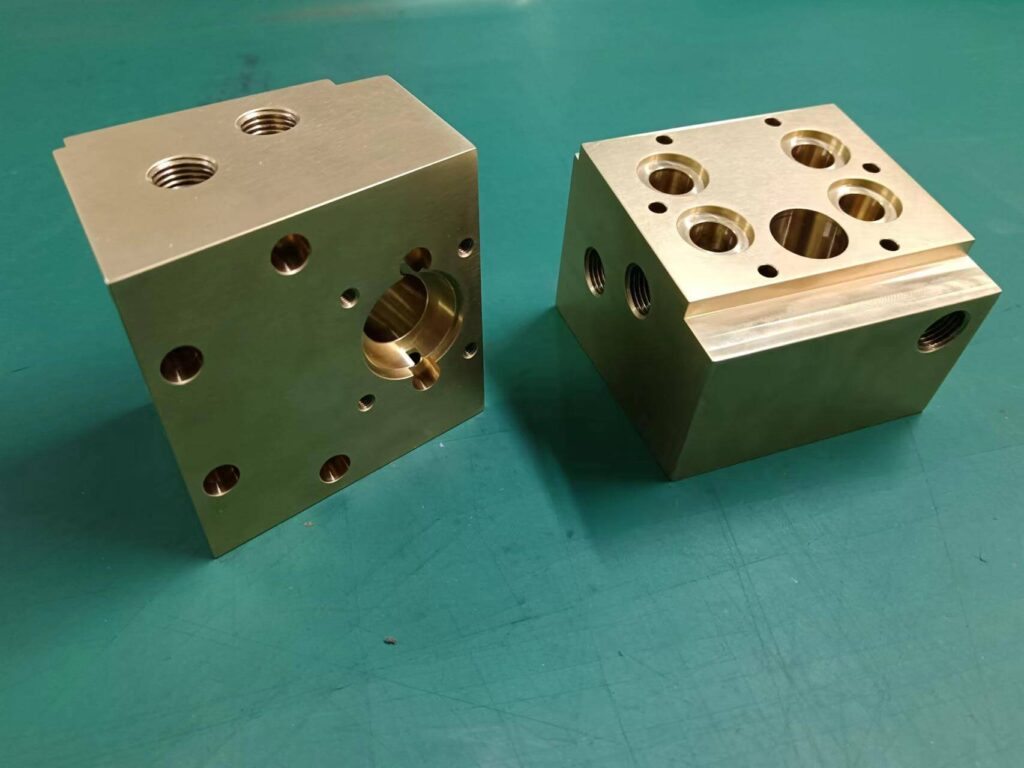

Stainless Steel

Stainless steel is chosen for its excellent corrosion resistance, durability, and suitability for medical and food-grade applications.

Carbon Steel

Carbon steel is commonly used for parts requiring strength and wear resistance, such as structural and automotive components.

Tool Steel

Tool steel is known for its exceptional hardness, wear resistance, and ability to hold a sharp edge, making it ideal for manufacturing durable and high-performance components.

Titanium

Known for its strength-to-weight ratio and corrosion resistance, titanium is commonly used in aerospace, medical, and marine applications.

Copper

With high electrical conductivity and resistance to corrosion, brass and copper are ideal for electrical connectors, fittings, and plumbing components.

Plastic

Plastics are often chosen for lightweight parts, insulators, and non-conductive components, especially in electronics and medical devices.

More Option

We welcome any customized materials according to your project for the machining parts with your drawing and requirement details.

Advanced On-Demand Manufacturing Solutions

With 25 years of machining expertise, we have served a wide range of industries:

Our in-depth knowledge of diverse applications, industry standards, and unique customer needs across these fields sets us apart, delivering unmatched value to our clients!

Why Choose SYM Machining Services?

SYM can fabricate any machined parts for your applications, just send us your drawing and get our best quote.

25+ Years of Experience

With over two decades of experience in the machining industry, SYM understands the complexities of working with aluminum and how to optimize material properties to deliver the best results.

Professional Equipments

Our advanced CNC machines, coupled with high-precision measuring tools, ensure that every aluminum part is produced to the exact specifications, meeting even the tightest tolerances.

Quality Control

Professional Q/C control and detailed photos support! Focus on every Details and track order picky.

NO MOQ

Whether you need a single prototype or thousands of units, SYM can handle orders of any size with the same level of care and precision.

Cost-Effective Solutions

Save 30-50% with our optimized production processes and strict cost management, delivering competitive pricing while maintaining exceptional quality standards.

Fast Delivery

We have professional team with Catalogue, Samples, Consults, Market Info. We combine quality workmanship, superior knowledge and nice prices.

What Our Customers Say

"We are grateful for your being such a great partner and for all your hard work in coordinating and rushing through our parts. You have helped us tremendously in our new product launch."

Mr.Zac B.

"I hope to be able to give you plenty of business in the future,your company has been a good and faithful supplier to us."

Mr.Louis K.

"We are all interdependent in business world, I am thankful for working together all these years. I respect you all and your company,I keep asking many questions,susan has always helped me which is extra time for her.I can't thank her enough."

Mr.Ravi K.

Latest News & Blogs

What is Custom Precision Machining

Discover why custom precision machining are essential for accurate, reliable, and high-performance manufacturing. Learn how to choose materials, reduce costs, and work with the right

Top 11 Reasons Custom CNC Milling Services Are a Game-Changer for Manufacturing

Discover everything about custom CNC milling services—from benefits and materials to costs and applications. Learn why CNC milling is vital in today’s precision manufacturing. Introduction

How to Choose the Right CNC Turning Shop

Picking the right manufacturing partner can make or break your project. Not all shops are created equal. Some focus on speed, others on high precision.